- Joined

- Feb 20, 2019

- Messages

- 335

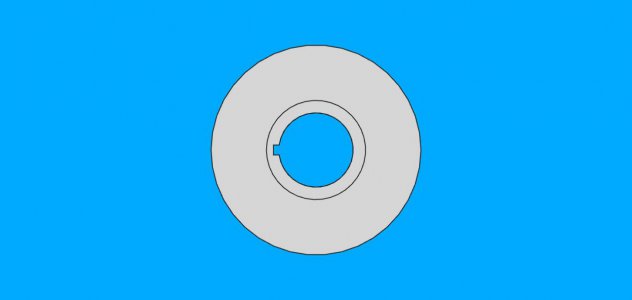

You sure your slitting saw was sharp? Some of those cheap HSS blades aren't much on steel. I bought a couple from Grizzly and they're fine on plastic or aluminum but dull within seconds on steel. I bought a Contrex carbide saw and it cut with little drag.......up until the part moved and it shattered into several pieces.