- Joined

- Jul 23, 2014

- Messages

- 347

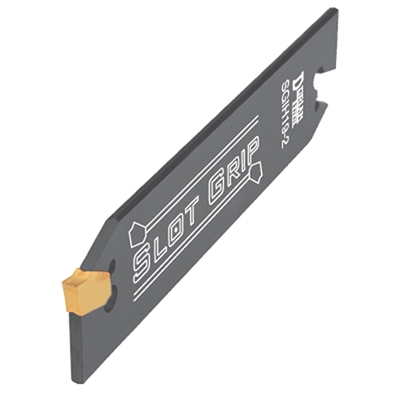

Do you think my 1440 E LB could make good use of this type of parting/cutoff blade? i.e. is the machine rigid enough etc.

I work mostly with steel. I like the idea of the insert being wider than the blade for deep cutting. Assuming thicker blade = more rigid doing deep cutting; what do you think would be the widest insert that my lathe could use effectively?

I work mostly with steel. I like the idea of the insert being wider than the blade for deep cutting. Assuming thicker blade = more rigid doing deep cutting; what do you think would be the widest insert that my lathe could use effectively?