- Joined

- Dec 3, 2013

- Messages

- 1,844

What CPU do you need?

Socket 775

What CPU do you need?

You would think. Unfortunately I need an older"ish" CPU for the board I have. I may have tracked one down, I'll know in the morning. My CS experience today with Newegg was absolutely unbelievable. Enough so I will never do business with them in the future.

If you were a bit closer, I would give a you MB. I have 6 or 7 of them sitting in my computer grave yard, just about in arms reach, and I think most of them work.

Best of luck

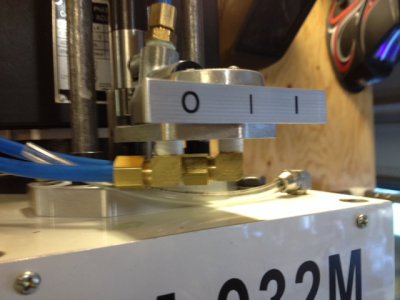

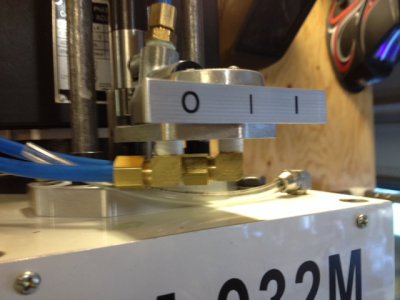

I was able to source a used CPU from a local computer repair shop and got my system back up and running last Friday in time to get the parts I needed done by Monday. Phew!!!

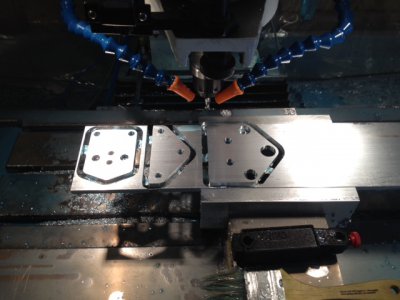

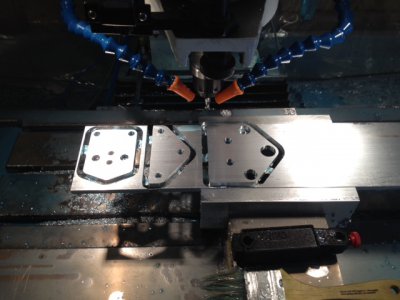

Monday I started on the power drawbar parts. For some reason on these parts I ran into finish problems on the outer contours. I'm assuming it is from chip buildup in the slot. I ran these parts with a 1/4" 2-flute end mill at 10in/min at 2000rpm with 0.025" DOC. Coolant was on full. I did not employ any finishing passes. Other parts in thicker material with 3/8" and 1/2" end mills did not have this problem so I was somewhat surprised. Either I need more coolant pressure/volume, run finishing passes or both?

Jay