-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM932 CNC Build

- Thread starter jbolt

- Start date

- Joined

- Dec 3, 2013

- Messages

- 1,844

Woo Hoo!!! got the z-axis powered up today and reattached the head. Feels good to finally be putting things back together.

The 4200 oz stepper moves the head likes it not even there. Parts for the chip tray wont be here until Tuesday so this weekend I will work on finishing the controller wiring.

Jay

The 4200 oz stepper moves the head likes it not even there. Parts for the chip tray wont be here until Tuesday so this weekend I will work on finishing the controller wiring.

Jay

B

bvd1940

Forum Guest

Register Today

Well good on ya, Im still waiting on my ballscrews:angry:

Things move slow out here in the sagebrush country.

Things move slow out here in the sagebrush country.

- Joined

- Dec 3, 2013

- Messages

- 1,844

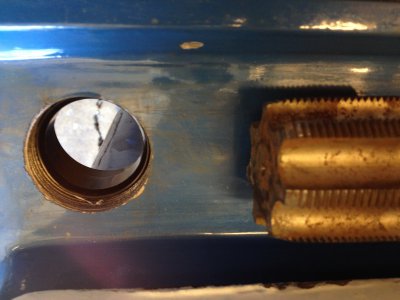

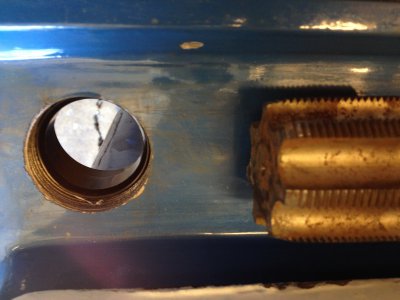

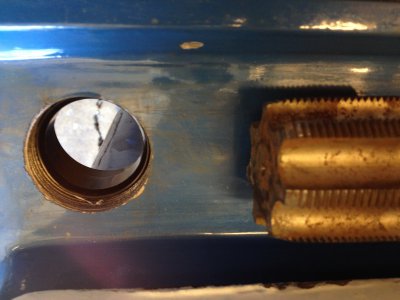

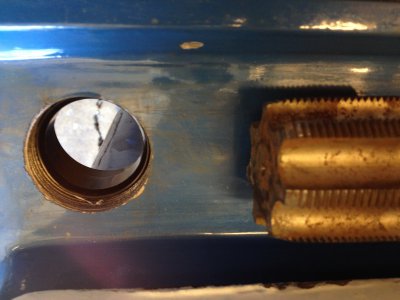

While waiting for the chip pan parts I worked on installing a sub frame to support the chip pan. I'm using the cast iron stand drip tray as part of the drainage system because it already had a drain hole and it allows a little more depth.. The hole from the factory is only 5/8" so I used a hole saw with a pilot bushing to open up the drain hole and used a 1-1/2" pipe tap to use 1-1/2" abs pipe for the drain pipe to the coolant bucket.

Jay

Jay

- Joined

- Dec 3, 2013

- Messages

- 1,844

Also spent some time on the machine wiring. I was able to reuse all of the machine electronics except 2 momentary switches used for the z up/down. I installed a new enclosure which is a little larger and mounted it to the column. By getting it off the gear head and setting it back I can get the head lower to the table when turned 90 deg. All of the machine controls are in one place. Only power and switch legs go the the stepper control box. In the enclosure the upper contactor runs the power for the spindle motor and also switches the latching circuit for the 2 other contactors. This way when the e-stop is triggered all power is cut. The 2 lower contactors split power to the stepper drives. Coming into the enclosure is a 40amp 220v circiut. This goes into a breaker tray which splits the power to a 220v 15A circuit for the spindle motor and 2 110v 15A circuits for the steppers, coolant pump machine lights and stepper enclosure fans.

Jay

Jay

- Joined

- Dec 3, 2013

- Messages

- 1,844

I picked up the chip pan parts on Friday and took it over the the robotics lab to assemble. The pan is 3 pieces, 2 sides and the lower tray. The lower tray has edge flanges all around. These are turned down to keep the inside of the pan clear of fasteners. The sides are sized so the tray locks inside the edge flanges. The tray was assembled with pop rivets and a Permatex gasketing sealant which is oil and water resistant. The assembled pan was then attached to the machine base using 10-32 flanged button head screws and the same gasketing sealant to the subframe I installed earlier.

Jay

Jay

B

bvd1940

Forum Guest

Register Today

I picked up the chip pan parts on Friday and took it over the the robotics lab to assemble. The pan is 3 pieces, 2 sides and the lower tray. The lower tray has edge flanges all around. These are turned down to keep the inside of the pan clear of fasteners. The sides are sized so the tray locks inside the edge flanges. The tray was assembled with pop rivets and a Permatex gasketing sealant which is oil and water resistant. The assembled pan was then attached to the machine base using 10-32 flanged button head screws and the same gasketing sealant to the subframe I installed earlier.

Jay

View attachment 74997View attachment 74998View attachment 74999

That is to pretty to mess up with chips and coolant:allgood:

- Joined

- Dec 3, 2013

- Messages

- 1,844

That is to pretty to mess up with chips and coolant:allgood:

I believe tools are meant to be used. I can't wait to get it messed up with coolant and chips!

Got your ball screws yet?

0

09kevin

Forum Guest

Register Today

Looks like you are doing a fantastic job! Do you plan on having any type of enclosure to keep the chips and coolant inside?

Kevin

Kevin

- Joined

- Dec 3, 2013

- Messages

- 1,844

Looks like you are doing a fantastic job! Do you plan on having any type of enclosure to keep the chips and coolant inside?

Kevin

Thanks Kevin.

I plan on doing a simple curtain enclosure out of pvc pipe and clear shower curtain liners. I don't want to do anything substantial so as to keep the machine accessible for oversized parts.

Jay