While I am waiting for the replacement ball screw I took a closer look at the BK bearing blocks that came with the ball screws. These hold the angular contact bearings that support the fixed end of the ball screw. I have no idea as to the quality of rating of the AC bearings but I do know they are not matched sets meaning they have no pre-load.

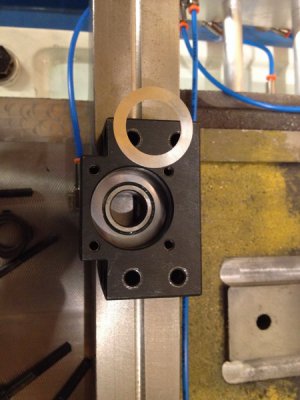

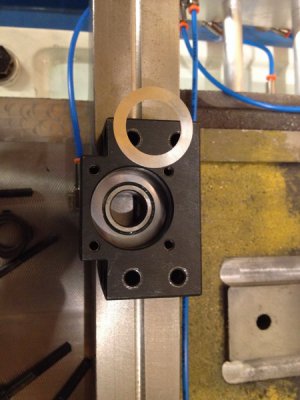

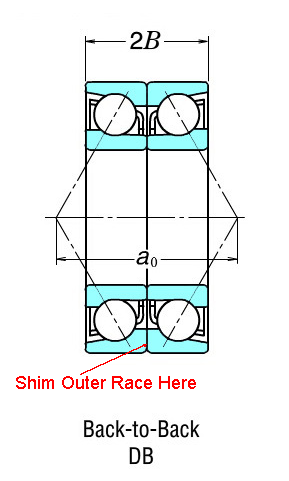

On top of that, with the bearing cap on the block there is extra space to let the bearings move back and forth. This turned out to be okay as it allowed space for shims to take up the slack in the bearings. Also note that the bearings were not orientated in any particular direction which is incorrect for the AC bearings.

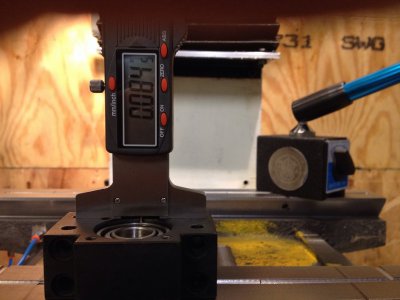

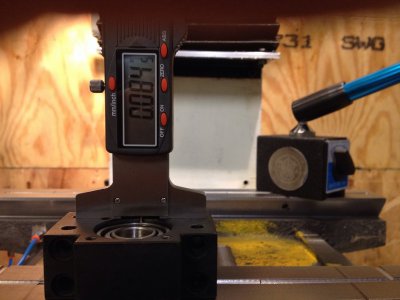

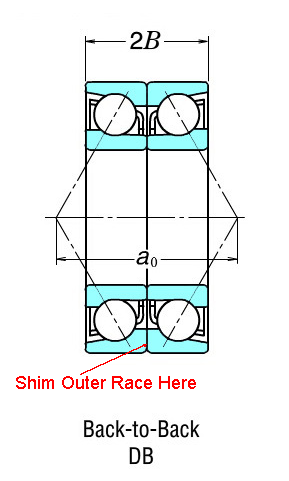

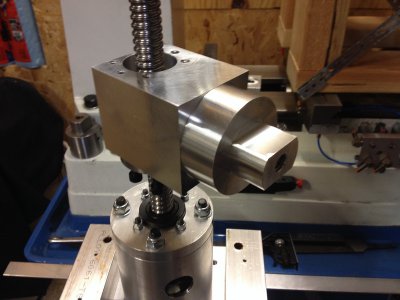

To measure the slop in the bearings and bearing block I installed the ball screw on the machine and locked down the center base. The bearings are oriented in the DB configuration. This is so shims can be installed in-between the outer races and keep the correct loading.

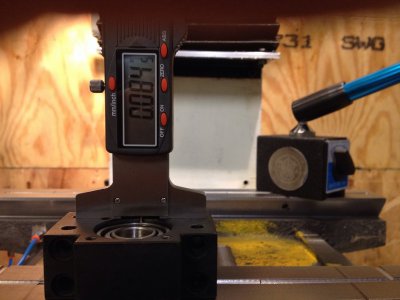

A dial indicator placed at the end of the screw is zero'd and by turning the screw until tight by hand it shows the combined bearing / block slop. (I used pliers on this shaft to crank on it since it is being replaced it doesn't t matter if it gets marred). With the bearing block cap removed I measured the setback of the bearings at the outer race and then the depth of the cap. This difference difference is subtracted from the overall slop measurement which gives the bearing slop. For example overall measurement = 0.014", Bearing block / cap setback slop = 0.008". 0.014" - 0/008" = 0.006" bearing slop.

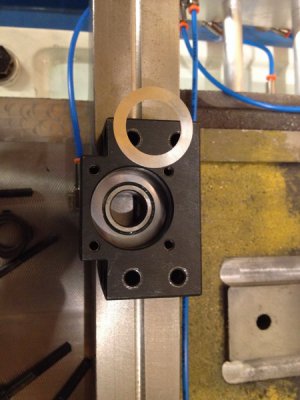

In this instance I installed 0.008" of shims. This tales up the slop and adds some pre-load. I have not taken the time to setup a jig to measure how much pre-load is really needed. I plan waiting until the machine is operational to see what the backlash is under machine load.

For the 2005 BK blocks they have 32mm OD bearings. I used 0.002" round shims.

http://www.amazon.com/gp/product/B006U1JMZ2/ref=oh_details_o00_s00_i00?ie=UTF8&psc=1 The shim OD had to be turned down to 32mm.

Another issue with the BK blocks is the cap is secured to the block with (4) 4mm 0.7 x 6mm cap screws. The BK cap under the screw head is 3mm which leaves only 3mm of thread engagement. Subtract the bevel at the threaded hole and you only get 2 threads engaged in the block. Not cool. Fortunately the holes are 15mm deep so the threads can the extended with a tap. I replaced the 6mm long screws with 12mm.

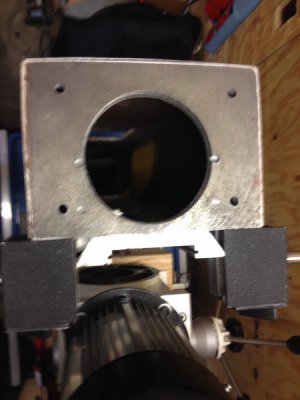

The AC bearing in the photo below is actually from VXB bearings. I managed to blowup one of the BK bearings while fitting them to the ball screw shafts and lost half the balls to my not so tidy and crowded garage floor. The VXB AC bearings are not expensive bearings so I'll see how the hold up compared the the BK bearings. The VXB do have less slop than the BK's.

Jay