- Joined

- Dec 3, 2013

- Messages

- 1,844

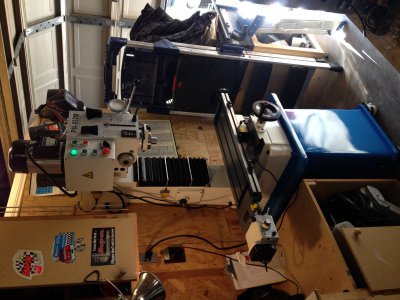

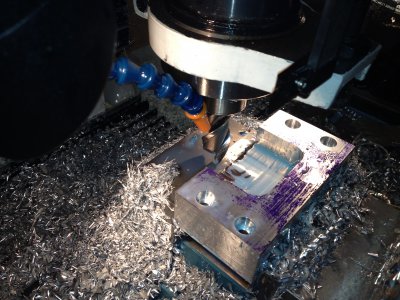

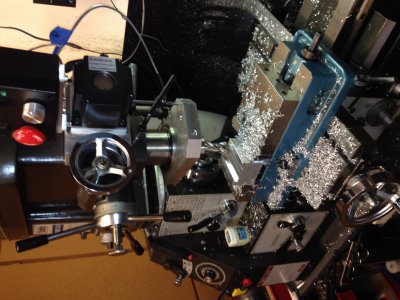

I had not planned on posting a build thread but since I have received a lot of information from other builds I figured I would give back.

My original build was going to be servo based but I ran across a great deal on stepper build parts similar to what jumps4 did on his zx45 conversion.

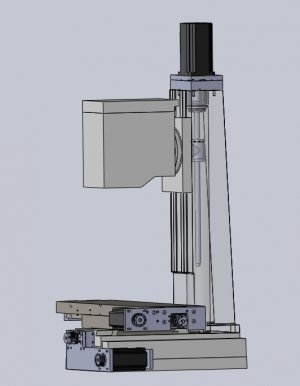

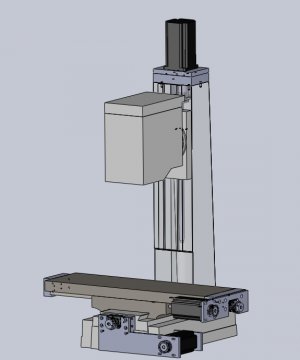

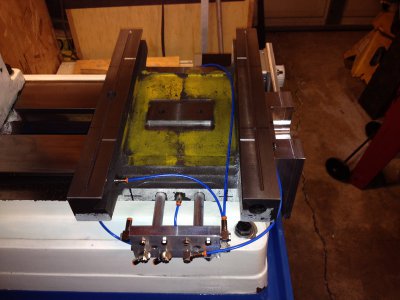

I have very limited space so the x & y steppers will be mounted off to the side with timing belts to the ball screws.

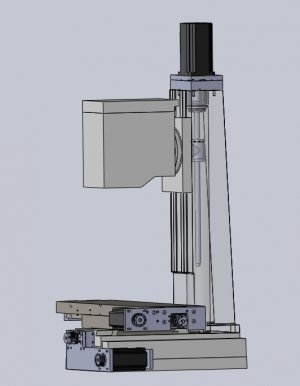

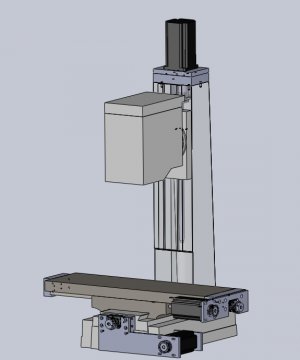

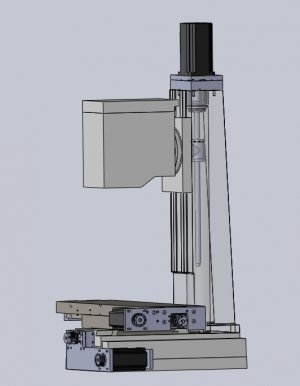

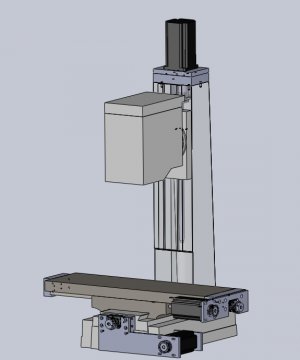

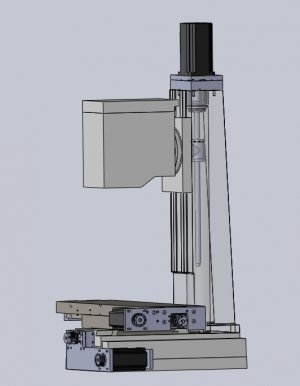

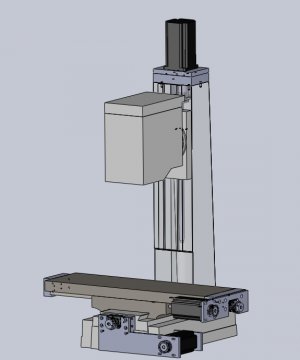

Here is a CAD screen capture of the layout done in Solidworks.

Jay

My original build was going to be servo based but I ran across a great deal on stepper build parts similar to what jumps4 did on his zx45 conversion.

I have very limited space so the x & y steppers will be mounted off to the side with timing belts to the ball screws.

Here is a CAD screen capture of the layout done in Solidworks.

Jay