- Joined

- Mar 13, 2017

- Messages

- 55

Hi all,

First I'd like to thank Mksj and Jbolt for all there help and guiding me through the process.

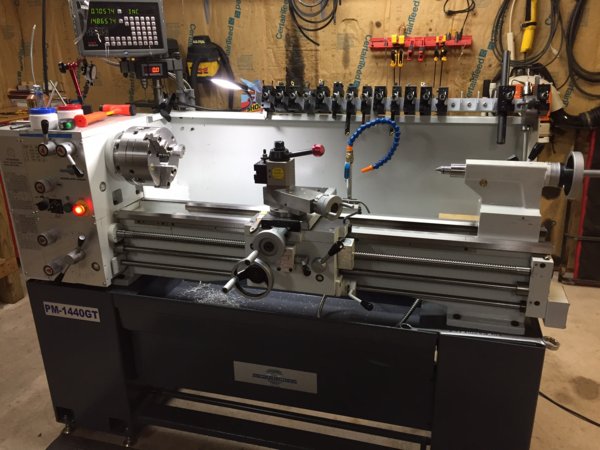

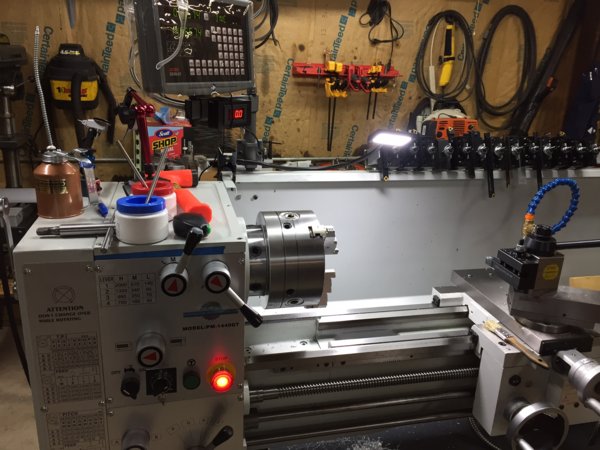

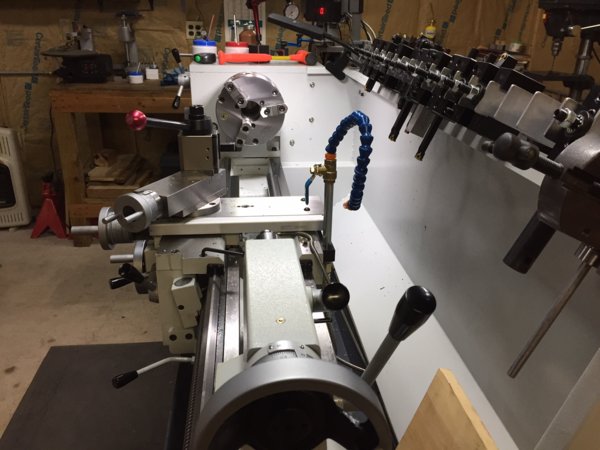

I mounted VFD in head stock base with a custom made bracket. I also added variable speed, 2 mode braking and free run for mauual brake.

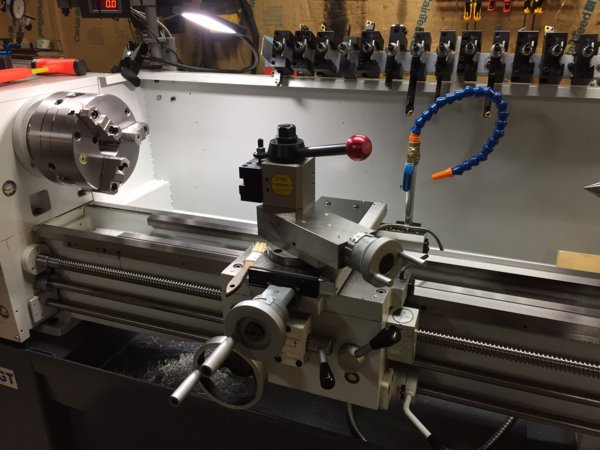

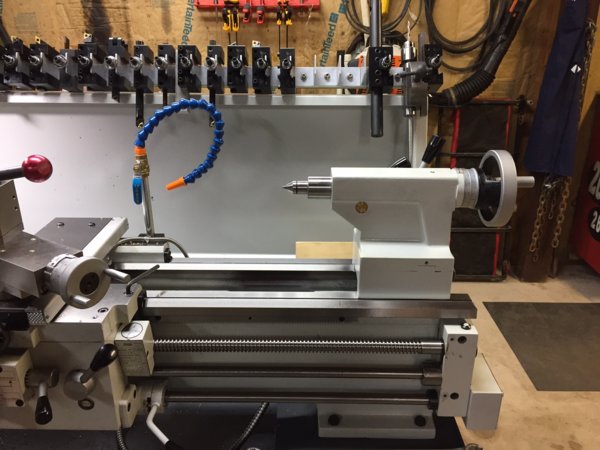

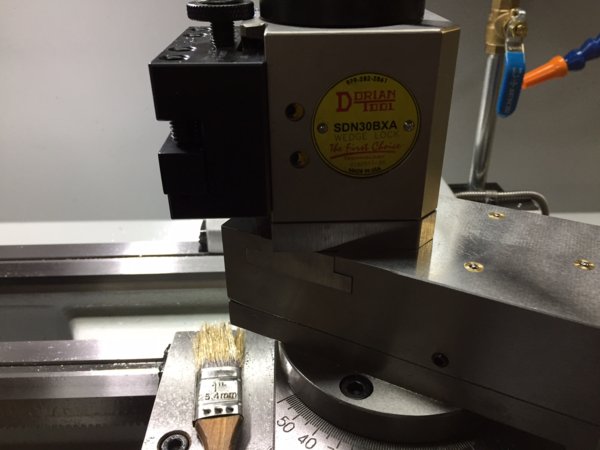

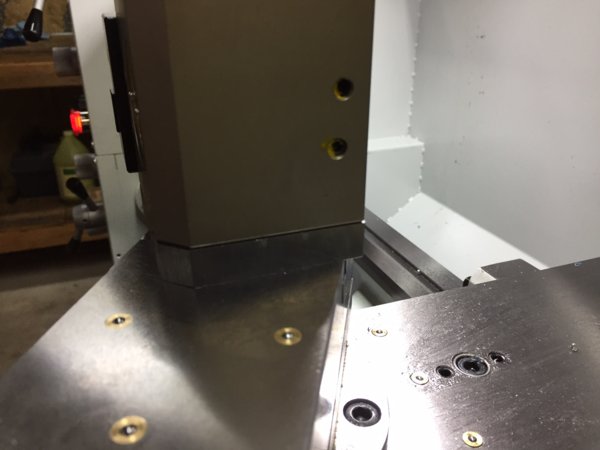

I was very limited to the sizes of tooling with the Dorian tool holders, 3/4 and 1" with no shimming. To me that kind of defeats the purpose of a QCTP and a hassle. I decided to shim the post instead with a ground 1/2" shim shaped and pinned to the tool post. Now I can use 3/8" to 1" tooling.

Thanks

First I'd like to thank Mksj and Jbolt for all there help and guiding me through the process.

I mounted VFD in head stock base with a custom made bracket. I also added variable speed, 2 mode braking and free run for mauual brake.

I was very limited to the sizes of tooling with the Dorian tool holders, 3/4 and 1" with no shimming. To me that kind of defeats the purpose of a QCTP and a hassle. I decided to shim the post instead with a ground 1/2" shim shaped and pinned to the tool post. Now I can use 3/8" to 1" tooling.

Thanks