- Joined

- Jun 12, 2014

- Messages

- 5,055

Not sure where to post this, but it can be adapted to most lathes. I built my spider support for the PM1340GT lathe awhile ago, but it was always a tight fit to the cover, the OD of the spider is 2.5". I had a set of spider holes very close to the cover, but could not use Allen cap screws because of clearance issues. After seeing a number of other lathe owners bore out their drive cover for their spiders, I decided to do likewise. My boring head was at it's max extension at 3", ran it at ~250 RPM and bored in 0.050" increments. The new spider hole was properly on center. I then proceeded to bore and tap another set of 4 staggered holes further out on my spider so I could use cap screws as an alternative. The cap screws are 3/8"-24 fine thread with 1/4" brass tips milled down to 0.200" at the tip.

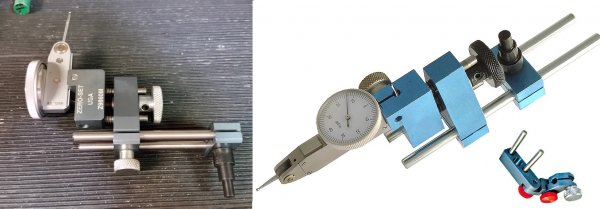

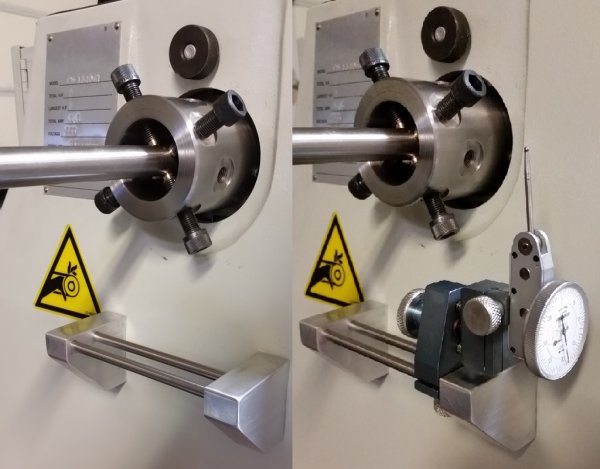

To indicate stock in the spider, I wanted something more permanent but easily removable, and that it wouldn't be in the way when I had finished using it. I ended up using an old Zero-Set indicator attachment, which is normally used to center holes on a mill. The dial test indicator is a long reach, so it clears the Allen screws when indicating. Inexpensive Zero-Set copies are available on the internet (eBay) for $30-40. Probably want one where the clamp on the bars is two pieces (for easy removal) as opposed to the one piece like Shar's. I mounted a simple dual rail system (two 0.250" bars on 0.750" centers) to the drive end cover using aluminum brackets, the Zero-Set slides back on the bar for use, and it has a vernier control for fine control, and they also have a height control. Shown I am indicating a 0.625" and 0.200" bar stock. Takes almost no time to true up the bar, and then just slide the indicator forward out of the way.

The support bars are adaptable to a wide range of add ons, indicators, etc. It is important to mock everything up to check your distances and clearances with the spider bolts fully extended. The PM1340GT cover has a vertical and a 7 degree slant where the blocks attach, so takes a little machining to fit the blocks to this cover.

Boring the drive cover.

Zero-Set plus copy

Spider indicator support

Indicating large and small rod

To indicate stock in the spider, I wanted something more permanent but easily removable, and that it wouldn't be in the way when I had finished using it. I ended up using an old Zero-Set indicator attachment, which is normally used to center holes on a mill. The dial test indicator is a long reach, so it clears the Allen screws when indicating. Inexpensive Zero-Set copies are available on the internet (eBay) for $30-40. Probably want one where the clamp on the bars is two pieces (for easy removal) as opposed to the one piece like Shar's. I mounted a simple dual rail system (two 0.250" bars on 0.750" centers) to the drive end cover using aluminum brackets, the Zero-Set slides back on the bar for use, and it has a vernier control for fine control, and they also have a height control. Shown I am indicating a 0.625" and 0.200" bar stock. Takes almost no time to true up the bar, and then just slide the indicator forward out of the way.

The support bars are adaptable to a wide range of add ons, indicators, etc. It is important to mock everything up to check your distances and clearances with the spider bolts fully extended. The PM1340GT cover has a vertical and a 7 degree slant where the blocks attach, so takes a little machining to fit the blocks to this cover.

Boring the drive cover.

Zero-Set plus copy

Spider indicator support

Indicating large and small rod