- Joined

- Dec 26, 2015

- Messages

- 2,079

After some hours of use on the Best & Jacobs Full Custom Edition PM1340, I decided it was time to improve rigidity of the toolpost by implementing a solid tool mount as a substitution for the compound when I don't need the function of the compound for normal turning activity.

In many ways, what I have done is a derivative of what's been done by Jbolt (http://www.hobby-machinist.com/threads/cxa-qctp-on-the-pm-1440gt.57630/#post-479360),

Robin Renzetti

and Stefan Gotteswinter

This implementation is specific to the PM1340 and Dorian BXA Quick change toolpost. I thought I'd document it here in case anyone else is crazy enough to want to attempt this kind of project.

The drawing of the solid tool mounting system I came up with is attached. My implementation is faithful to the drawing.

The first step was to remove the cross slide from the lathe and drill and tap it for mounting the solid tool post mounting system and the registration block. When the solid mount is removed and replaced with the compound, the mounting holes will receive button-head cap screws.

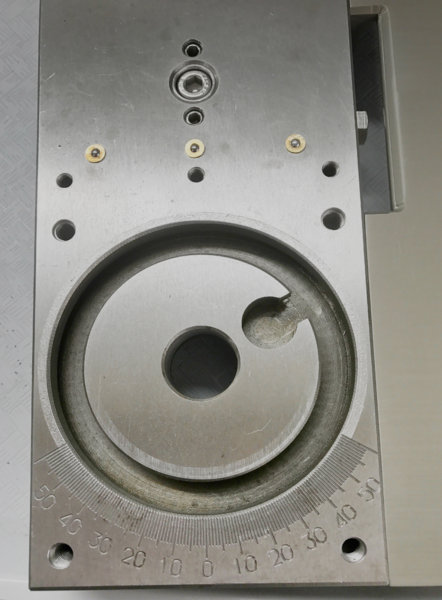

For the solid mount, I started with a 28 pound chunk of 1018 I ordered from Speedymetals.com. I squared the block and brought it to final outside dimensions and drilled a center hole which is the basis for all the drawing dimensional references - this hole is concentric with the rotational pivot of the compound and allowed me to re-register the solid block on the mill after it was taken to the lathe for test fitting.

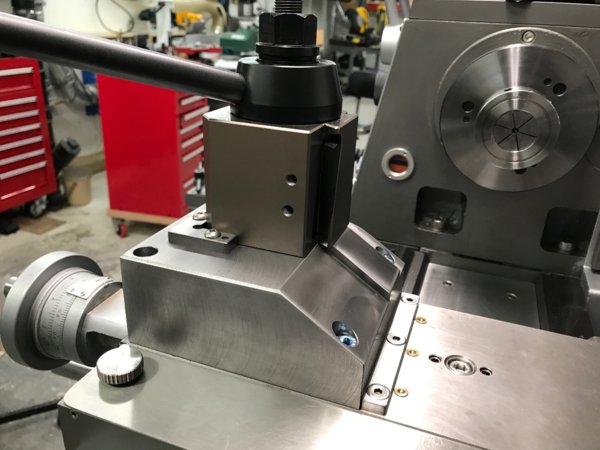

Next step - drill the solid mounting block for the mounting bolts, the Dorian toolpost dowel pins, mounting shaft, etc.

Then test fitting the Dorian BXA QC toolpost, and checking "wiggle room" in the dowel pin indexing system.

Good fit. Next step was to finish detailing the solid tool mounting block with chamfers for chip-falls, etc.

And the most critical step, bringing the final height of the solid tool mount to the exact same height as the compound - this way the individual tool holder height registrations are the same whether using the compound or the solid tool mounting system. The compound height was established on a granite reference plate using a DTI on indicator stand, then the solid mount machined and checked against that as reference. On my PM1340, the top surface of the compound is exactly 2.222-inches above the cross slide. Your mileage may vary - check first.

Test mounting of the solid tool mount to the cross slide - checking for fit, registration, etc. I got lucky - everything aligned as hoped.

After checking the alignment of the Dorian BXA to the spindle centerline and the cross slide movement (video here: https://www.flickr.com/photos/davidpbest/34683487541/in/album-72157684102384825/ ), everything was locked down in preparation for the addition of alignment and registration blocks that would make it easy to remove either the solid tool mount and/or the Dorian BXA QC tool post, and have those same items go back onto the lathe registered and secured to a known position and alignment.

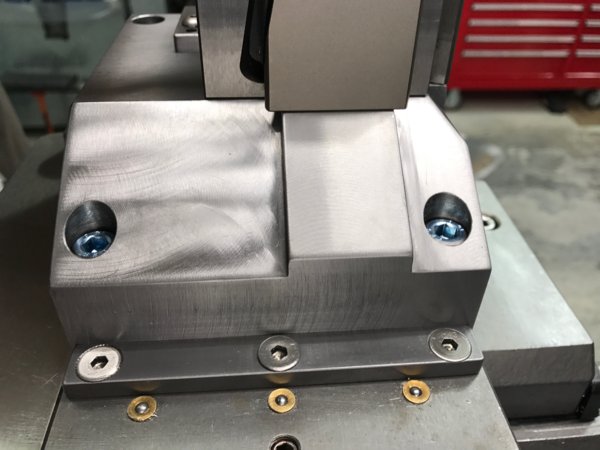

This shows the corner registration block that locks the Dorian toolpost from rotation under load, and registers the toolpost to the same position each time it's secured to the solid mount. The corner block is preloaded against the two 10mm dowel pins that extend from the bottom of the BXA tool post into the solid tool mount. The amount of preload against the two dowel pins is 0.1mm in both X and Z. The inside edges of the corner block are slightly beveled so that the toolpost is forced into registration against the two dowel pins as it's tightened down on the mounting shaft.

After positioning the corner block on the lathe and making sure the Dorian toolpost was properly aligned to the lathe, the solid mounting was taken to the mill, the corner block preload knocked in, then the corner block was drilled and two 4mm dowel pins installed through it and into the solid mount using Loctite.

And finally, an alignment block was added to the cross slide. This ensures the solid mount registers to the same X position each time it's installed, and that it's axial position remains consistent. This registration block is low enough in profile that the compound (when installed) can rotate freely above it.

Since completing this tonight, I've only had a few minutes to test it out, but some things are already clear. The rigidity is indeed improved. I can now do heavy knurling on stainless steel without the tool post twisting around out of position, and the surface finish on 1018 steel is better. In the next few days, I'll be giving it a full workout - focusing on parting-off difficult materials - and will report back once I have a bit more time in use. Fingers crossed.

Sorry for the long post. Hope this is useful to someone here. If anyone wants the drawing, the PDF is attached.

In many ways, what I have done is a derivative of what's been done by Jbolt (http://www.hobby-machinist.com/threads/cxa-qctp-on-the-pm-1440gt.57630/#post-479360),

Robin Renzetti

and Stefan Gotteswinter

This implementation is specific to the PM1340 and Dorian BXA Quick change toolpost. I thought I'd document it here in case anyone else is crazy enough to want to attempt this kind of project.

The drawing of the solid tool mounting system I came up with is attached. My implementation is faithful to the drawing.

The first step was to remove the cross slide from the lathe and drill and tap it for mounting the solid tool post mounting system and the registration block. When the solid mount is removed and replaced with the compound, the mounting holes will receive button-head cap screws.

For the solid mount, I started with a 28 pound chunk of 1018 I ordered from Speedymetals.com. I squared the block and brought it to final outside dimensions and drilled a center hole which is the basis for all the drawing dimensional references - this hole is concentric with the rotational pivot of the compound and allowed me to re-register the solid block on the mill after it was taken to the lathe for test fitting.

Next step - drill the solid mounting block for the mounting bolts, the Dorian toolpost dowel pins, mounting shaft, etc.

Then test fitting the Dorian BXA QC toolpost, and checking "wiggle room" in the dowel pin indexing system.

Good fit. Next step was to finish detailing the solid tool mounting block with chamfers for chip-falls, etc.

And the most critical step, bringing the final height of the solid tool mount to the exact same height as the compound - this way the individual tool holder height registrations are the same whether using the compound or the solid tool mounting system. The compound height was established on a granite reference plate using a DTI on indicator stand, then the solid mount machined and checked against that as reference. On my PM1340, the top surface of the compound is exactly 2.222-inches above the cross slide. Your mileage may vary - check first.

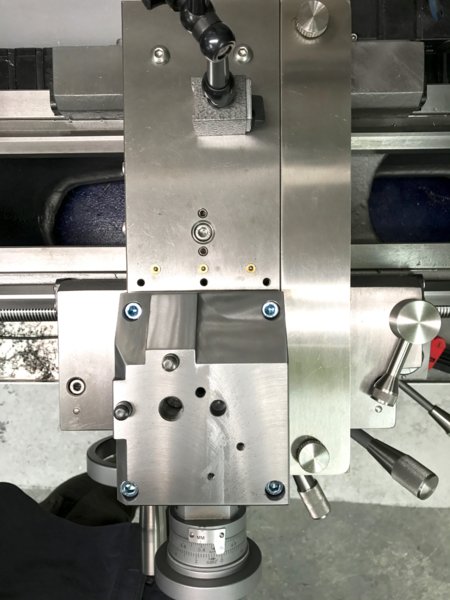

Test mounting of the solid tool mount to the cross slide - checking for fit, registration, etc. I got lucky - everything aligned as hoped.

After checking the alignment of the Dorian BXA to the spindle centerline and the cross slide movement (video here: https://www.flickr.com/photos/davidpbest/34683487541/in/album-72157684102384825/ ), everything was locked down in preparation for the addition of alignment and registration blocks that would make it easy to remove either the solid tool mount and/or the Dorian BXA QC tool post, and have those same items go back onto the lathe registered and secured to a known position and alignment.

This shows the corner registration block that locks the Dorian toolpost from rotation under load, and registers the toolpost to the same position each time it's secured to the solid mount. The corner block is preloaded against the two 10mm dowel pins that extend from the bottom of the BXA tool post into the solid tool mount. The amount of preload against the two dowel pins is 0.1mm in both X and Z. The inside edges of the corner block are slightly beveled so that the toolpost is forced into registration against the two dowel pins as it's tightened down on the mounting shaft.

After positioning the corner block on the lathe and making sure the Dorian toolpost was properly aligned to the lathe, the solid mounting was taken to the mill, the corner block preload knocked in, then the corner block was drilled and two 4mm dowel pins installed through it and into the solid mount using Loctite.

And finally, an alignment block was added to the cross slide. This ensures the solid mount registers to the same X position each time it's installed, and that it's axial position remains consistent. This registration block is low enough in profile that the compound (when installed) can rotate freely above it.

Since completing this tonight, I've only had a few minutes to test it out, but some things are already clear. The rigidity is indeed improved. I can now do heavy knurling on stainless steel without the tool post twisting around out of position, and the surface finish on 1018 steel is better. In the next few days, I'll be giving it a full workout - focusing on parting-off difficult materials - and will report back once I have a bit more time in use. Fingers crossed.

Sorry for the long post. Hope this is useful to someone here. If anyone wants the drawing, the PDF is attached.

Attachments

Last edited: