-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm1228 Dro

- Thread starter donnyfl

- Start date

-

- Tags

- dro installation pm1228

- Joined

- Jun 12, 2014

- Messages

- 4,808

Your lathe should be similar to the Sieg C8 and C10. I would look at this install for some ideas: http://www.mini-lathe.com/projects/dro_pros/dro_pros.htm

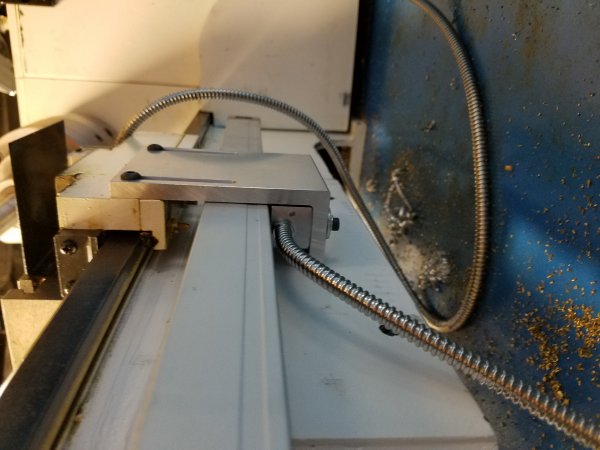

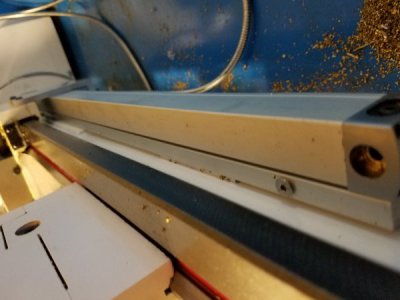

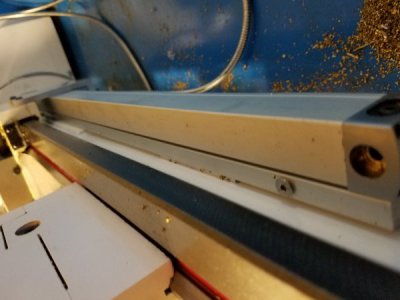

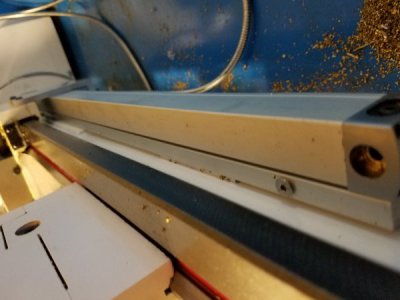

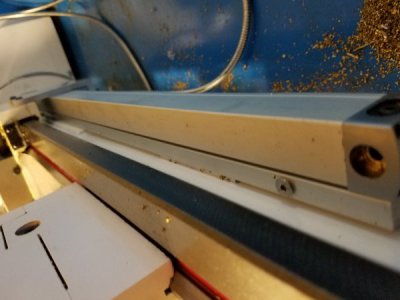

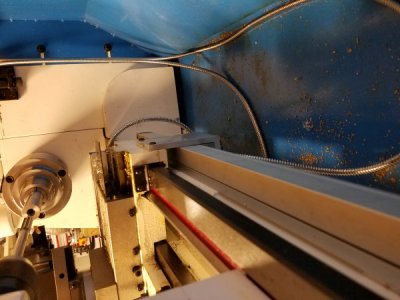

This is the magnetic scale, the glass scales are moumted with the reader head down as opposed to perpendicular.

This is the magnetic scale, the glass scales are moumted with the reader head down as opposed to perpendicular.

Sweet this definitely helps mksj! Thank you

Your lathe should be similar to the Sieg C8 and C10. I would look at this install for some ideas: http://www.mini-lathe.com/projects/dro_pros/dro_pros.htm

This is the magnetic scale, the glass scales are moumted with the reader head down as opposed to perpendicular.

I will try and take some pics later today for you. I installed it nearly identical to the above link. The only issue with that is you can not use the follow rest as the scale covers the mounting holes on the saddle. This was not very important to me. I did not use many of the brackets.. or if memory serves me correctly I modified a few.

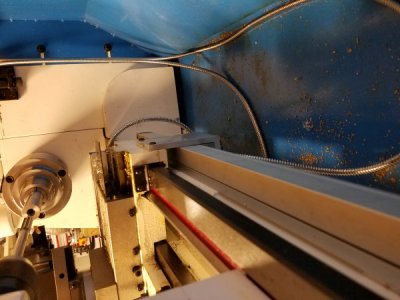

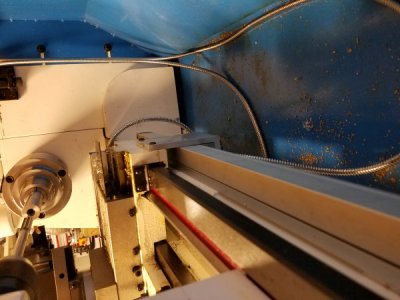

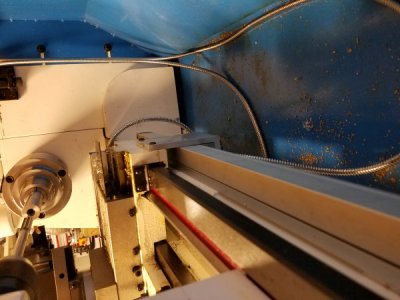

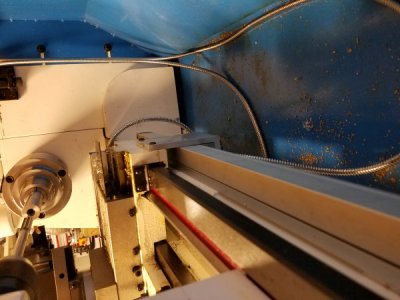

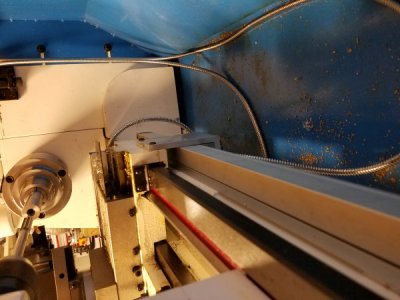

Donny here you go. For the x axis installing it on this side is the easiest but you cant use your follow rest unless you take off the scale. I have had no problems with chips getting into the scale. I had plans for two screws on the mounting bracket between the ways but I could not get a drill in there so I needed to simply put one in the middle.

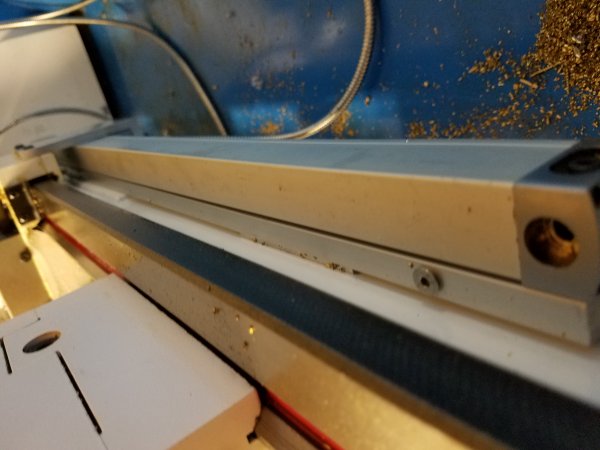

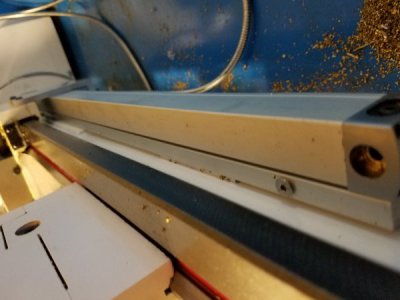

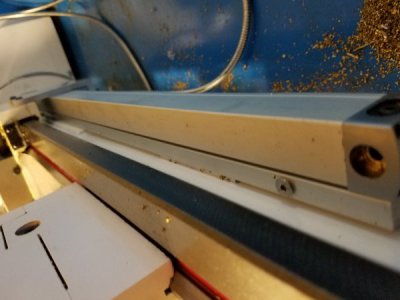

For the Z there is a small bump out on the back of the casting. I need a ~.125" shim to get the scale to run parallel with the apron due to this bump out. Use an indicator to ensure it is running both parallel and flat with the apron.

Some of the pics are rotated.. sorry.

Hope this helps.

For the Z there is a small bump out on the back of the casting. I need a ~.125" shim to get the scale to run parallel with the apron due to this bump out. Use an indicator to ensure it is running both parallel and flat with the apron.

Some of the pics are rotated.. sorry.

Hope this helps.

You're awesome JD thank you! The Y looks so much easier now that I've seen your setup. As for the X, that was your own bracket correct? Since I don't have that.

I believe I modified one of the brackets it came with.. I cant recall. I think I just milled down the length of both legs of the Angle Bracket and relieved some material to get it to fit between the ways. I also removed the inner bend radius from the angle so it would sit completely flat on the cross slide. As mentioned I wanted to have 2 fastening points to the cross slide but I was only able to drill and tap 1 given the spacing between the ways.

- Joined

- Oct 7, 2016

- Messages

- 3

Hey JD. Your install looks great!

I am having an issue with the DRO that you might help with. The long axis works great, but the values for the cross axis look to be scaled by 5 (0.1" movement shows up as 0.5" on the DRO). I am working in "radius" mode, so the diameter function is not on. I see several factors in the DRO setup menu, but changing them does not seem to make any difference. Of course the manual is not much help.

Thanks!

I am having an issue with the DRO that you might help with. The long axis works great, but the values for the cross axis look to be scaled by 5 (0.1" movement shows up as 0.5" on the DRO). I am working in "radius" mode, so the diameter function is not on. I see several factors in the DRO setup menu, but changing them does not seem to make any difference. Of course the manual is not much help.

Thanks!

- Joined

- Jun 12, 2014

- Messages

- 4,808

The cross slide scale is usually 1 micron, if you have the DRO setup for a 5 micron scale (which is often the default value) you will get a 5X increase in the displayed value read vs. actual movement. Change the scale resolution to 1 micron. Also the R/D function is setup for only one axis, on a lathe DRO that is usually the X axis. This same issue was just reviewed in another posting: http://www.hobby-machinist.com/threads/dro-problem.58744/#post-484024