-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM-1236 Cast Stand?

- Thread starter SSage

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,852

There is a photo of it on Matts recently updated sister site (last photo). http://www.precisionmatthews.com/shop/pm-1236/

Yeah, what budget? I'm thinking I should go with the cast stand if I can get one.

After reading the threads about the sheet metal stands lacking stability, maybe the cast one is heavy enough to help with that. I'll check into one after the holiday. I guess you can build a wood shelf in the left side to store lube. There is no door in the pic. But, the front access panels on both cabinets looks like an advantage.

After reading the threads about the sheet metal stands lacking stability, maybe the cast one is heavy enough to help with that. I'll check into one after the holiday. I guess you can build a wood shelf in the left side to store lube. There is no door in the pic. But, the front access panels on both cabinets looks like an advantage.

- Joined

- Jun 12, 2014

- Messages

- 4,805

Given the nominal increase cost ($200) for the cast iron base, I would definitely recommend it when you look at relative to the total cost of the machine. The additional rigidity and weight go a long ways to making a smother machine, also cast iron has very good vibration dampening affects. I have often seen posting of a number of individuals reinforcing or adding weight to the sheet metal bases of their 1236 machines. Usually the foot brake mechanism goes through the headstock cabinet, making it unusable for storage. It is a big overall expense, so if you need to wait a bit longer to accumulate funds, in this case I think it is well worth it. I also have to give Kudos's to QMT for always trying to make their machines better and also trying to give his customers the most bang for their buck. Buyers (including myself) all need to be mindful that everything is built to a price point, so there are always some compromises the less expensive the machine.

- Joined

- Jan 27, 2017

- Messages

- 184

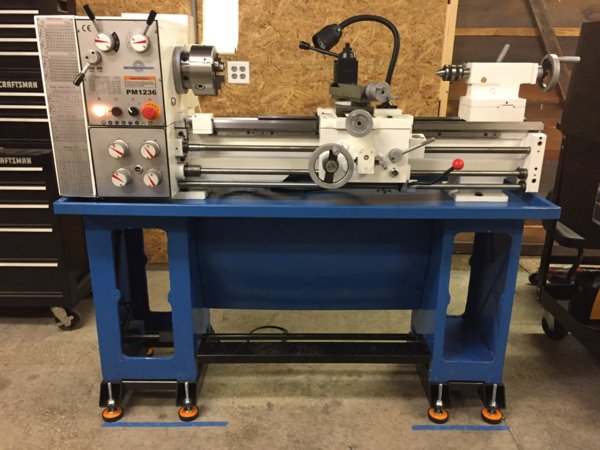

I'm out of town so I'm posting the pictures I happened to have on my phone. The bases are very solid and not light by any means. Not ideally set up for storage but with a little creativity there are some options. In all of my pictures the covers are removed - I'm thinking that I may use magnets to reattach the front panels instead of screws for easier access.

I added bases beneath for height but I opted not to connect between the two. From the little bit of time that I have on the 1236 the set up seems very solid. I don't think you would be disappointed going with the cast iron.

I added bases beneath for height but I opted not to connect between the two. From the little bit of time that I have on the 1236 the set up seems very solid. I don't think you would be disappointed going with the cast iron.

I'm out of town so I'm posting the pictures I happened to have on my phone. The bases are very solid and not light by any means. Not ideally set up for storage but with a little creativity there are some options. In all of my pictures the covers are removed - I'm thinking that I may use magnets to reattach the front panels instead of screws for easier access.

I added bases beneath for height but I opted not to connect between the two. From the little bit of time that I have on the 1236 the set up seems very solid. I don't think you would be disappointed going with the cast iron.

The pics answered my questions, thanks.

I was thinking about raising up the stand too, you must be a tall fellow! I'm just under 6'-4" with a 32" inseam bare foot, that looks a bit tall, but my legs are not that long. I'll have to wait and see, waiting is the bad thing about the PM1236, at least its not months. The added base looks good though, nice execution with the choice of steel. I usually have to tweak the heights in my shop so I can work all day without too much pain. I'll probably end up doing something, I need to raid my scraps pile and see if I have something workable.