- Joined

- Dec 20, 2012

- Messages

- 9,422

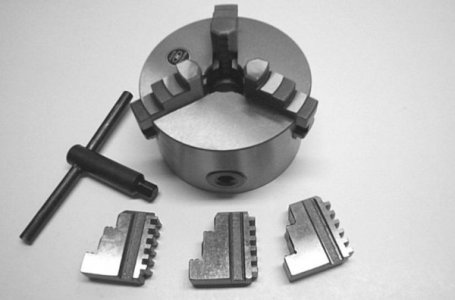

Every high quality chuck I've seen has numbered jaws and jaw slots. Typically, the factory will hand fit the jaws to make sure the jaw fits without binding before numbering them. Some chucks, like Rohm, will fit the jaws and certify the accuracy of the chuck by tightening only one pinion; that pinion will be marked and the chuck should be tightened onto the work with that pinion. Otherwise, the accuracy of the chuck may not fall within specs.

The point: if your jaws are numbered then use them as marked. If not, then as long as the jaws fit without binding it should be okay. If you want the best accuracy from them, swap the jaws and check run out with a dowel pin until you find the best combination, then mark them yourself and mark the pinion that produced that best result. Once done, it should hold the tolerances the combination can produce.

The point: if your jaws are numbered then use them as marked. If not, then as long as the jaws fit without binding it should be okay. If you want the best accuracy from them, swap the jaws and check run out with a dowel pin until you find the best combination, then mark them yourself and mark the pinion that produced that best result. Once done, it should hold the tolerances the combination can produce.

Last edited: