- Joined

- Jul 20, 2012

- Messages

- 1,237

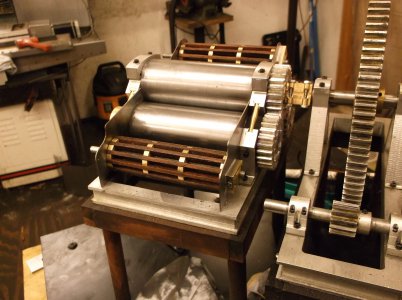

Can this be a new sticky thread? See lot of interest in doing Home Shop CNC but not many pictures of actual parts made. Even internet wide not so many pictures of what has actually been made.

Let's see people show off things and others get ideas of what is possible!

Let's see people show off things and others get ideas of what is possible!