- Joined

- Aug 1, 2022

- Messages

- 137

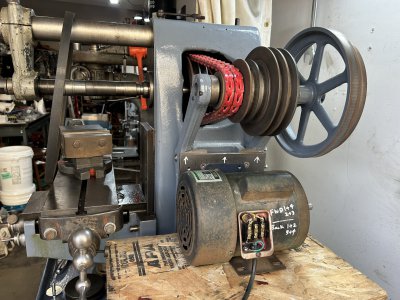

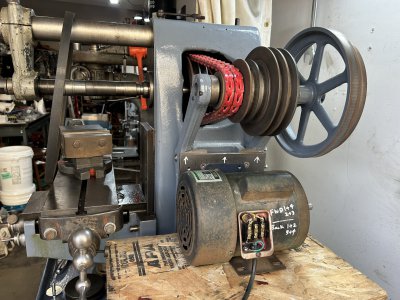

I picked up a B-12 in great condition. Just slowly getting it in position and running.

Had to sell a small mill first to make room for it. Then I had to swap out the 3ph motor with a 110v single phase. Of course I’ll have to drill/tap new holes in the mounting plate. Then as I started it up, the capacitor on the 35 year motor started leaking and smoking… well, at least it’s already drilled/tapped for a standard 56C mounting. Thinking about getting a new capacitor to see if that fixes it, but I found a good deal on a new/old stock motor.

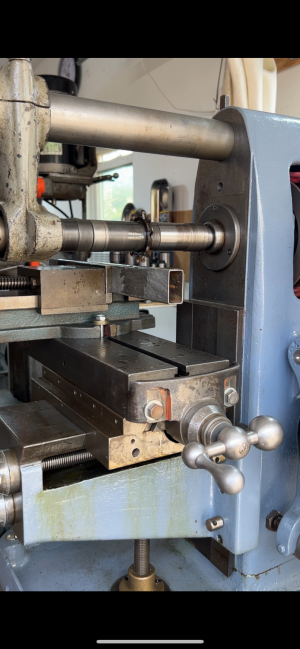

While waiting for the new motor, I decided to make new crank handles for the y and z, since the shared crank it came with has an enlarged square hole. Waiting for a square broach before welding it all up.

I already have a task waiting to go on the horizontal mill once it’s done.

Had to sell a small mill first to make room for it. Then I had to swap out the 3ph motor with a 110v single phase. Of course I’ll have to drill/tap new holes in the mounting plate. Then as I started it up, the capacitor on the 35 year motor started leaking and smoking… well, at least it’s already drilled/tapped for a standard 56C mounting. Thinking about getting a new capacitor to see if that fixes it, but I found a good deal on a new/old stock motor.

While waiting for the new motor, I decided to make new crank handles for the y and z, since the shared crank it came with has an enlarged square hole. Waiting for a square broach before welding it all up.

I already have a task waiting to go on the horizontal mill once it’s done.