Can confirm. I just pulled my 12" apart last week – spring only, no ball.

will.... dont know if was stupid move or not for me BUT............ yep there it is BUT.....

i pulled the pin on the bull gear. to far out... wasnt able to push it back in...

now i have no clue how it was all to work anyways...

soooooooooooooo guess what comes next... PULL THE SPINDLE apartttttttttttttt. grrrrrrrrrrrrrr

ok not so bad all done... iam sort of glad i did this...

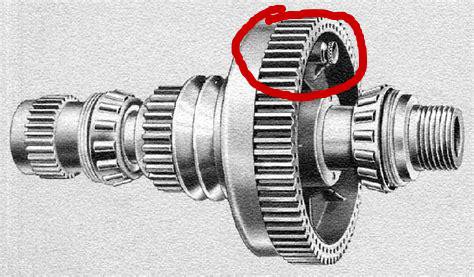

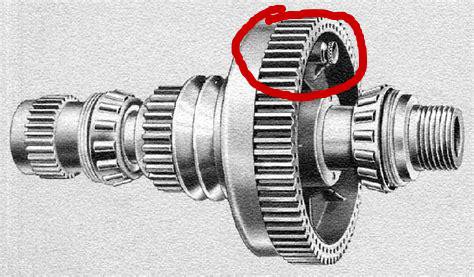

so i find that the pin in the bull gear.. has a spring and a ball... in the bullgear itself. that holds the pin... the pin has a cut out indent for the ball to sit as so the pin doesnt fly out.. I HAD NO CLUE OF THIS .. till now.. i think the kid who had it twisted the pin so the indent was facing up to the lil hole that you can see in the bullgear.

so no parts missing ..

i thought the pin held into the hole on the belt pully.. as to stop the bullgear from moving left right on spindle. NO it doesnt .

what i found was ... lil grub screw on the bullgear for the main shaft or spindle shaft. whatever its called... so i check on the spindle shaft for marks. where that grub screw might have grabed. it is 180 degress off the woodruf key . theres marks... so i sung the grub screw just a hair and the gear now sits tight. i took the index pin out on the casing itself for now.. it scared me lol.. had it tick a few times. dont want it to take out the bullgear.

sooooo clean real good. pull the outter bearing covers. clean clean clean... glad i did.. it did need to be cleaned.. wasnt bad but it had some crap in the cover to the bearings. races were nice and smooth. no heat or grind marks. no checking or cracking in the races or cages. bearing pins all nice and smooth nothing on them. no heat or grind marks .

so all nice and clean. oiled . put back togther with the right amount of tightness to the left spindle nut. just like the old chevy wheel bearing setup hahhaha ..

only issue left really is the middle jack shaft. there is nooooooo oil holes.... not the bottom one .. this is the atlas with its drive motor in the cabinet under it not off the back.. there is one above the motor then that feeds the head. she is a lil noisey not like grinding but ...... its heading that way... something tells me ill have to pull it apart and replace the bearings and maybe drill some sort of oil hole in the casing for it ..

anyways all is good... spun her up to full bore. 2200 rpm i think is max. sounded sooooooo quite .... down to 400 rpm nothing.. so she is done for now ..

i know the drawing is very bad. but gives idea. hahhahah as you can see the lil black ball and below it would be the spring red line. the black thing top right is the pull pin.. all the pin does is mate the belt pully and bullgear. it doesnt hold them togther. i had no clue on this..