- Joined

- Jan 23, 2015

- Messages

- 25

Recently I bought a Grizzly G0602 lathe. I set it up and completed the required break-in without any troubles. As the owner's manual suggested I changed the oil immediately. Within a few hours there was a significant oil leak from the gear box. In a few days all the oil drained out. It was obvious that the leak was between the case and the front cover along the bottom edge. Page 84 of the manual shows an exploded diagram (boom!) of the gear box. It doesn't show a gasket of any kind.

I called Grizzly for technical assistance. Is there a gasket? Should there be a gasket? Do they have one cut to fit? It turns out that there is no gasket. Tech support could only guess at what was causing the leak, but they recommended removing the cover and using RTV to reseal it. By the way, the folks and Grizzly showed a great deal of concern and wanted to help. This post is not a criticism of Grizzly.

Removing the cover wasn't too difficult. All you have to do is remove four cap screws. The cover was painted on and stuck tight. After a couple of whacks with a rubber mallet, the cover fell on the floor, just missing my foot, and about a half cup of oil splashed onto my leg and the floor.

(Note to self: in the future hold onto the cover and put down a pan to catch the oil.)

After cleaning the floor and me I inspected the cover and the case. A bead of sealant had been put between the cover and the case. If you guessed that the sealant was thinnest along the bottom edge you would be correct. (It was thickest along the top edge. I guess gravity is different in China than here.) It could be that the way the sealant was put on may have contributed to the leak, but that's a guess.

Anyway, I put an adequate amount (I hope) of RTV around the edge of the cover and replaced everything. Oil will be put back after a 24 hour cure.

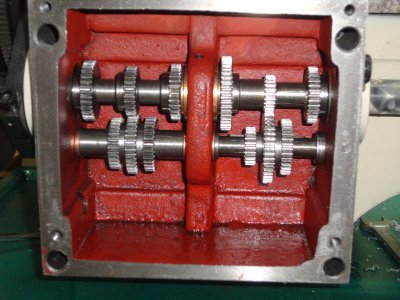

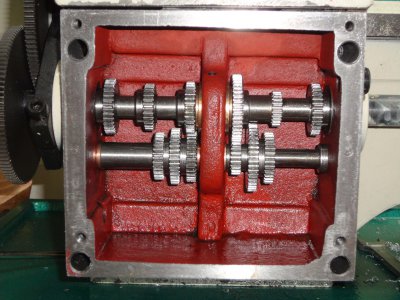

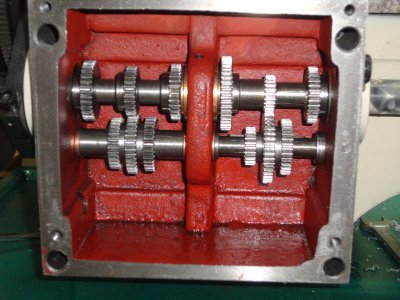

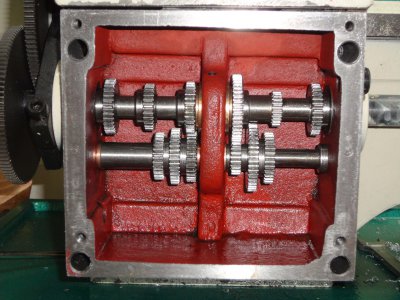

I took some pictures of the open gearbox and the back of the cover plate. The two gear trains are shown in different positions, C-III and B-II. The two large gears on either side split the shift forks on the back of the cover. When you operate the knobs on the front the forks engage the sides of those gears and move the respective gear train.

I called Grizzly for technical assistance. Is there a gasket? Should there be a gasket? Do they have one cut to fit? It turns out that there is no gasket. Tech support could only guess at what was causing the leak, but they recommended removing the cover and using RTV to reseal it. By the way, the folks and Grizzly showed a great deal of concern and wanted to help. This post is not a criticism of Grizzly.

Removing the cover wasn't too difficult. All you have to do is remove four cap screws. The cover was painted on and stuck tight. After a couple of whacks with a rubber mallet, the cover fell on the floor, just missing my foot, and about a half cup of oil splashed onto my leg and the floor.

(Note to self: in the future hold onto the cover and put down a pan to catch the oil.)

After cleaning the floor and me I inspected the cover and the case. A bead of sealant had been put between the cover and the case. If you guessed that the sealant was thinnest along the bottom edge you would be correct. (It was thickest along the top edge. I guess gravity is different in China than here.) It could be that the way the sealant was put on may have contributed to the leak, but that's a guess.

Anyway, I put an adequate amount (I hope) of RTV around the edge of the cover and replaced everything. Oil will be put back after a 24 hour cure.

I took some pictures of the open gearbox and the back of the cover plate. The two gear trains are shown in different positions, C-III and B-II. The two large gears on either side split the shift forks on the back of the cover. When you operate the knobs on the front the forks engage the sides of those gears and move the respective gear train.

![IMG_1184[1].JPG IMG_1184[1].JPG](https://www.hobby-machinist.com/data/attachments/75/75947-5b8def1cf57c347ad6a01c1abce005a5.jpg)