- Joined

- May 4, 2015

- Messages

- 3,583

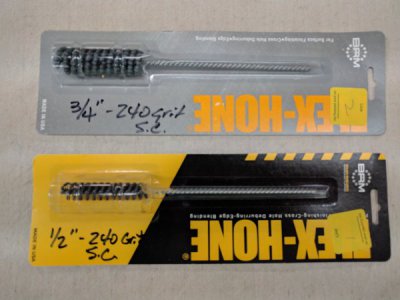

I think they offer them in different grits , if there used in increasing finer grits the will enlarge the boring up to the final polish . Not as much as a stone hone but with better finishes. I use to polish and lengthen forcing cones in shotgun barrels , used eds red and it worked really well.