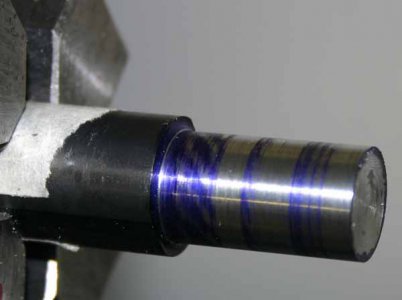

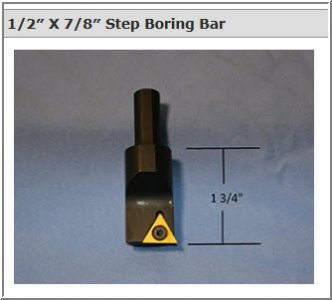

This was more of an experimental thing, wondering if anyone has done similar? My boring head has 1/2" holes. Thus far I've been using Borite cutters. For a whopping 18$C including shipping I bought this CCMT insert boring bar off AliExpress which is quite similar to what I use on the lathe. Its the next bigger (metric) size, they don't do inches. I lopped it off (sacrilege!) & turned down the end. My 3J chuck didn't quite grip it properly due to the opposing 2 flats orientation so a 4J chuck is much better. Seemed like reasonably tough mystery material but nothing onerous.

I thought about making the turn down length such that the stock bar would flush contact the boring head underside. But aside from aesthetics, I couldn't see a good reason. If the bar ever rotated it would scratch up my shiny boring head But the main thing is it has a lot more meat than a stock boring bar anyway. I could give it a bit of chamfer just for looks. Which brings me to my question:

But the main thing is it has a lot more meat than a stock boring bar anyway. I could give it a bit of chamfer just for looks. Which brings me to my question:

I was just about to replicate the flat on the round (turned down boss) in order to preserve the insert cutting tool angle when the boring head set screw aligns to this flat. Another plus is the material is not hardened so any set screw marks will occur on the flat vs. the buggering up the round & make removal problematic. I guess right now without a flat I have the ability to alter the angle anyway I like. But do you think there is any reason to? They seem to work pretty good in the lathe with set rake & this is essentially the same operation, just vertically no?

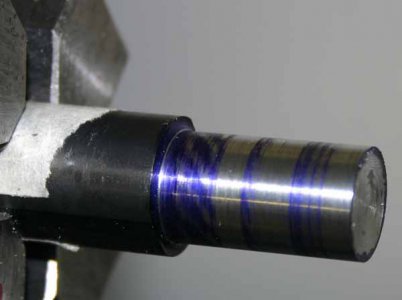

Showing a large radius stick-out-the-side mode. I wouldn't run it like this but this was kind of the general idea of butchering up the bars - I could make myself a graduated set of lengths for pretty reasonable cost.

I thought about making the turn down length such that the stock bar would flush contact the boring head underside. But aside from aesthetics, I couldn't see a good reason. If the bar ever rotated it would scratch up my shiny boring head

I was just about to replicate the flat on the round (turned down boss) in order to preserve the insert cutting tool angle when the boring head set screw aligns to this flat. Another plus is the material is not hardened so any set screw marks will occur on the flat vs. the buggering up the round & make removal problematic. I guess right now without a flat I have the ability to alter the angle anyway I like. But do you think there is any reason to? They seem to work pretty good in the lathe with set rake & this is essentially the same operation, just vertically no?

Showing a large radius stick-out-the-side mode. I wouldn't run it like this but this was kind of the general idea of butchering up the bars - I could make myself a graduated set of lengths for pretty reasonable cost.