- Joined

- Sep 9, 2014

- Messages

- 90

I really get tired of trying to get a sufficient amount of oil into the little spring loaded oilers on my machines. My oiler is an older pump type that works perfectly until I try to use it on the oil hole caps. The Plews oiler has very small groves in the tip which are supposed to allow the oil past the ball. Not so much. I end up wiping up more oil than I get into the machine.

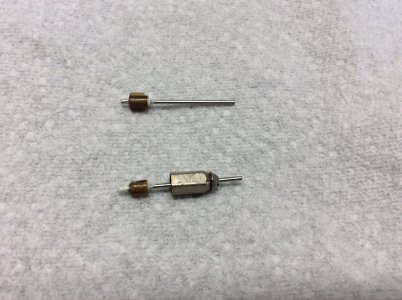

One day I was using a small needle oiler on some other parts and stuck it into the oil cap and bingo, oil went where I wanted and I wiped up very little. The light came on over my head. Why not insert a needle into the end of my pump oiler?

I found that a # 19 syringe needle fit the end of the oiler almost perfectly. I cut the pointy end off with my belt sander so I wouldn't inject myself with lubricant. Then I removed most of the plastic from the other end with a wire stripper to avoid damaging the needle and trimmed it to fit into the oiler tip. Screwed the tip back on with the needle in it and now lubing the machines is easy with little waste.

The Plews oilers are all over eBay and cheap. The older ones are best ( USA made ).

Now regarding the oil. When it comes lubrication, most of us have our preferences. Manufacturers usually suggest a particular kind of lubricant for the various parts of their machines. That, however, is merely a recommendation and certainly not cast in stone, often paid for by the company making the lube.

Quite a few years ago, and after a lot of research, I began using synthetic lubricants in all my vehicles. The reasons were many, but primarily to squeeze as many MPG’s out of them as I could. Also because of the longer drain intervals.

One day I needed to lube the ways on my lathe but had no more way oil so I used some synthetic engine oil I had. Everything moved easier. When I would wipe swarf off the ways, the oil tended to stay put unless I wiped real hard, and even then it was still there. I now use only synthetic engine oil for all my equipment.

Why not? It has a very high lubricity factor. It clings tenaciously to metal. It has exceptional shear strength. It's a designer oil made for the most extreme conditions. It prevenst rust. It doesn't dry out or evaporate. It won't gum up in extremely cold weather. It withstands extreme heat without break down. For what you get it's not expensive. A quart will last a long time. And,for what it's worth, it makes a great gun oil for a lot less money. For what you would pay for four ounces of gun oil you can buy a quart of synthetic motor oil. No one said you could only use it in an engine. I use 0-20 AMSOIL because it's not heavy, but other synthetics work just as well.

I hope this helps someone searching for a better lubricant.