I think this would be a no-brainer, but I'm learning that I don't know everything so before I plunge in...I just picked up a low end machinist vise, (Shars brand from WT), during my usual R&R of this type of thing, found the drive screw bearing absolutely bone dry.I know it must be lubricated, but is it supposed to be greased as a high RPM bearing would be, or should I use a lighter oil?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New vise/Dry bearing

- Thread starter Taz

- Start date

- Joined

- Mar 1, 2012

- Messages

- 1,140

I know your vise isn't a Kurt but the manual for Kurt vises says to use water resistant marine grade grease on the thrust bearing.

- Joined

- Sep 7, 2012

- Messages

- 64

Water resistant marine grease since they are used around coolant fluid?

Dale

Dale

Thanks! At the risk of embarrassing my sub-platinum grade vice, if it's good enough for a Kurt. Appreciate it brother!

I'm actually pretty surprised, not only are they (Shars) embarrassingly honest when it comes to the quality of their product, leaving paint runoff, ugly cast edges etc... in their pics -> http://www.shars.com/products/gallery/69/202-1030D.jpg/. The working parts and surfaces are all awesome as far as I'm concerned, apart from ugly chamfers. I paid the same for this as I did my last HF bench vise, and the two can not be compared. I've never owned a vise like this before, but it's got a pretty clever mechanism for moving the jaw, and exerting downward force on the bed (<-- proper term?) as it's finally tightened.

I'm actually pretty surprised, not only are they (Shars) embarrassingly honest when it comes to the quality of their product, leaving paint runoff, ugly cast edges etc... in their pics -> http://www.shars.com/products/gallery/69/202-1030D.jpg/. The working parts and surfaces are all awesome as far as I'm concerned, apart from ugly chamfers. I paid the same for this as I did my last HF bench vise, and the two can not be compared. I've never owned a vise like this before, but it's got a pretty clever mechanism for moving the jaw, and exerting downward force on the bed (<-- proper term?) as it's finally tightened.

I didn't think about that. I have some "Super Lube", synthetic grease. It's not stated as marine grade but it passes 100hr salt water spray test, I imagine that would be sufficient. Thanks for the help guys.Water resistant marine grease since they are used around coolant fluid?

Heard you guys like pictures so...

Not too bad for a $100 vise, and a couple evenings of fun.

Before:

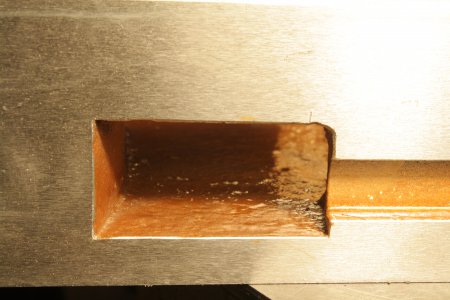

This thing was pretty nasty.

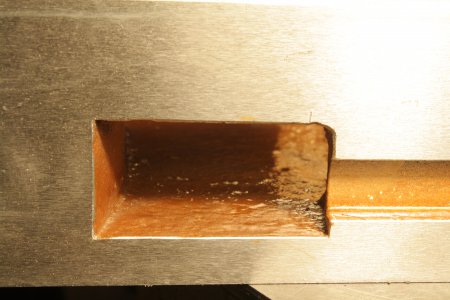

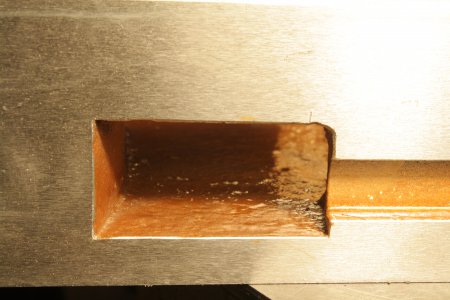

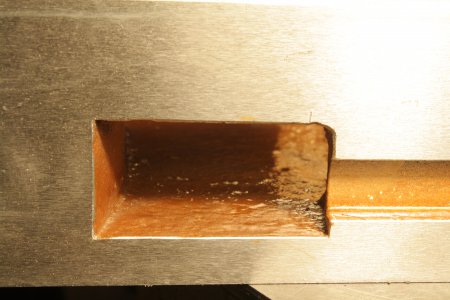

Even worse inside. WTH is up with this ugly flat red smudge I'm seeing all over steel?

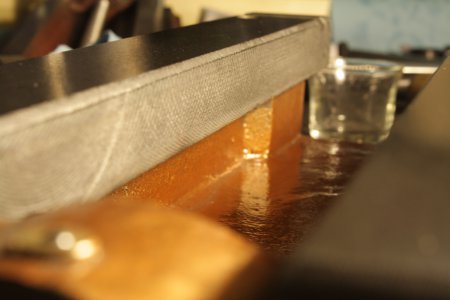

New paint.

It's not perfect, but a hell of an improvement.

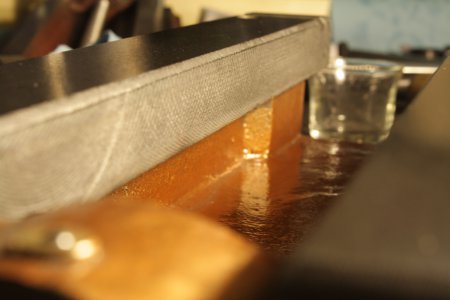

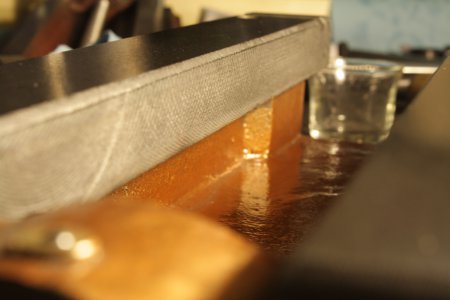

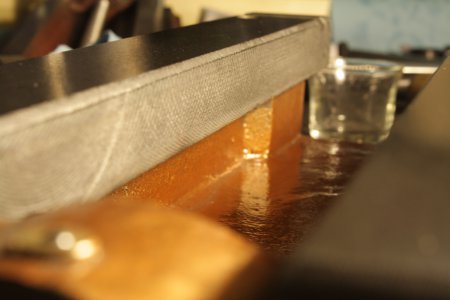

Looks wet in there but it's not.

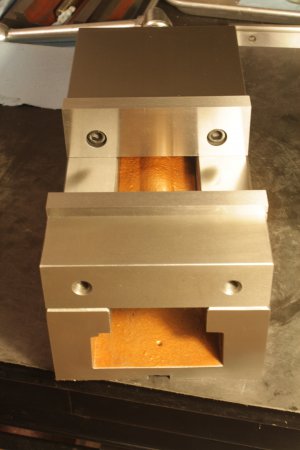

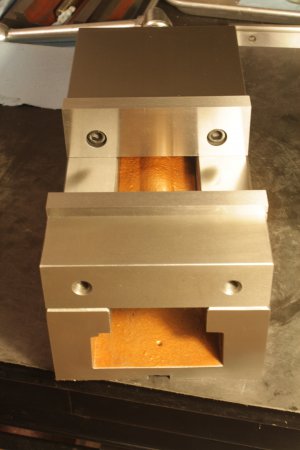

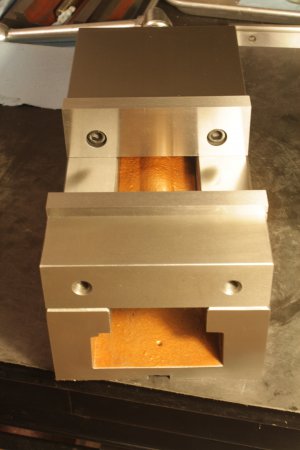

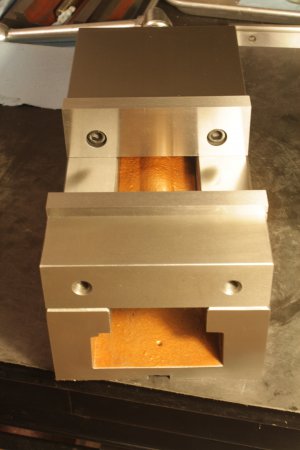

The result.

One thing I noticed while cleaning up the chamfers, is that the steel was extremely hard in most places, but near any of the holes, and especially the key slots, it was completely annealed. My file sounded like marble on concrete in the middle, but as soon as I got to the key slot for the fixed jaw, it sunk in like a hot knife in butter. Apart from all the fluffy stuff which I actually enjoy fixing up (I actually think it kind of a treat), this is one of several things I found that spoke to it's low price, and couldn't be easily remedied. The casting was also pretty poor, with lost of small voids, and some discoloration that couldn't be buffed out, and you can see in the last shot, on the end, where the lock-down nut slides appears notched (inside-top-left) on one side and not the other. Funny too that there were 4 different colors of paint inside. The nicest piece was the sliding jaw block, it had a nice blue flake paint inside the casting void. Wonder what vise that came off of? Any way, fun little project, still wound up being a pretty nice little vise. Thanks again for help!

Not too bad for a $100 vise, and a couple evenings of fun.

Before:

This thing was pretty nasty.

Even worse inside. WTH is up with this ugly flat red smudge I'm seeing all over steel?

New paint.

It's not perfect, but a hell of an improvement.

Looks wet in there but it's not.

The result.

One thing I noticed while cleaning up the chamfers, is that the steel was extremely hard in most places, but near any of the holes, and especially the key slots, it was completely annealed. My file sounded like marble on concrete in the middle, but as soon as I got to the key slot for the fixed jaw, it sunk in like a hot knife in butter. Apart from all the fluffy stuff which I actually enjoy fixing up (I actually think it kind of a treat), this is one of several things I found that spoke to it's low price, and couldn't be easily remedied. The casting was also pretty poor, with lost of small voids, and some discoloration that couldn't be buffed out, and you can see in the last shot, on the end, where the lock-down nut slides appears notched (inside-top-left) on one side and not the other. Funny too that there were 4 different colors of paint inside. The nicest piece was the sliding jaw block, it had a nice blue flake paint inside the casting void. Wonder what vise that came off of? Any way, fun little project, still wound up being a pretty nice little vise. Thanks again for help!