- Joined

- Jan 2, 2014

- Messages

- 9,295

Hi All,

I get spoiled at work because they have quality microscopes at the rework benches for soldering surface-mount components. Our typical resistors are "0402" size, that's 40 thou. by 20 thou. (1.0 mm × 0.5 mm). They are also great for finding and removing the inevitable metal slivers!

I recently stumbled across the exact same model at my local used-tool dealer; so I bought it!

It came with a small stand, but when I mentioned I wanted one with a longer arm he threw in a heavy, long-arm stand.

So the project is to make this microscope:

fit this stand:

That big stand weighs more then the old stand and microscope put together.

I needed enough clearance so that the knobs on the vertical dovetail of the microscope did not hit the knob on the stand. Also, I wanted to maintain a large height adjustment range to accommodate all kinds of items under the 'scope.

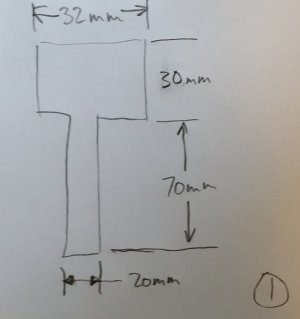

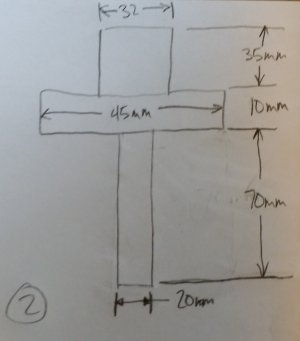

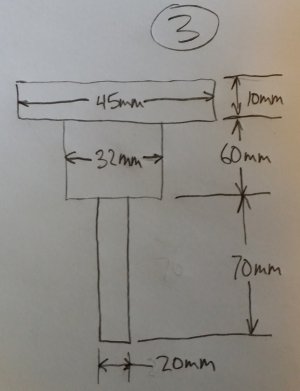

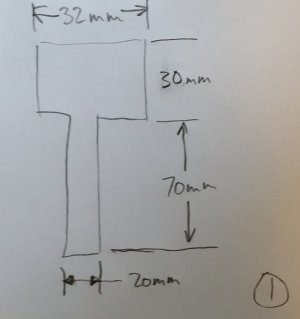

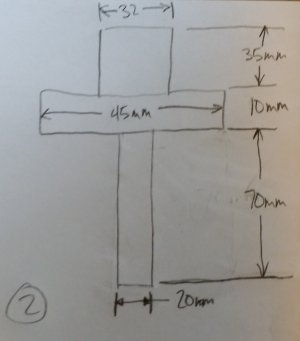

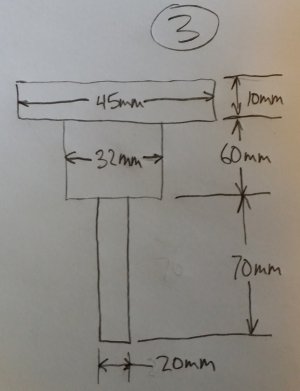

I sketched up a few ideas:

...and decided on the last one.

I decided to make it in two pieces rather than waste a bunch of material turning the 20mm section out of the >45mm diameter bar. I used a press fit to hold the 20mm shaft into the other section. Here's a shot of the part I made along with the raw stock it came from.....

Unfortunately, I was having sooooo much fun machining that I forgot to take many pictures during the actual work. However here's one shot of the big end still on the lathe. I turned it in the chuck with a tail-stock live centre. This picture was before it was drilled and bored for the press-fit.

Here it is installed between the heavy base and the microscope::

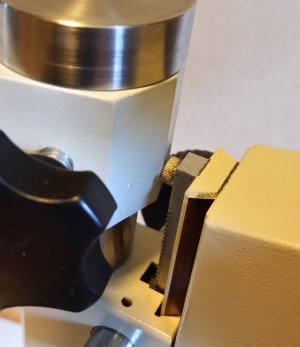

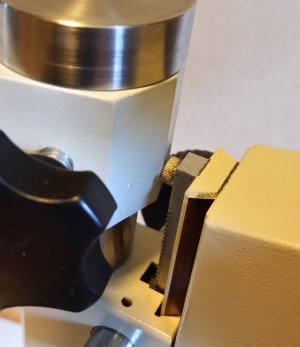

I had one small interference problem with one of the original SHCS for the rack when the vertical dovetail was cranked way up:

I just swapped that SHCS to a Philips head screw and got some clearance:

Still to do:

-I want to drill and tap the bottom small end so I can use a SHCS and washer so the 'scope cannot fall off the bottom end.

-I need to make some camera mounts and tubes to fit a camera to the third port

-brino

I get spoiled at work because they have quality microscopes at the rework benches for soldering surface-mount components. Our typical resistors are "0402" size, that's 40 thou. by 20 thou. (1.0 mm × 0.5 mm). They are also great for finding and removing the inevitable metal slivers!

I recently stumbled across the exact same model at my local used-tool dealer; so I bought it!

It came with a small stand, but when I mentioned I wanted one with a longer arm he threw in a heavy, long-arm stand.

So the project is to make this microscope:

fit this stand:

That big stand weighs more then the old stand and microscope put together.

I needed enough clearance so that the knobs on the vertical dovetail of the microscope did not hit the knob on the stand. Also, I wanted to maintain a large height adjustment range to accommodate all kinds of items under the 'scope.

I sketched up a few ideas:

...and decided on the last one.

I decided to make it in two pieces rather than waste a bunch of material turning the 20mm section out of the >45mm diameter bar. I used a press fit to hold the 20mm shaft into the other section. Here's a shot of the part I made along with the raw stock it came from.....

Unfortunately, I was having sooooo much fun machining that I forgot to take many pictures during the actual work. However here's one shot of the big end still on the lathe. I turned it in the chuck with a tail-stock live centre. This picture was before it was drilled and bored for the press-fit.

Here it is installed between the heavy base and the microscope::

I had one small interference problem with one of the original SHCS for the rack when the vertical dovetail was cranked way up:

I just swapped that SHCS to a Philips head screw and got some clearance:

Still to do:

-I want to drill and tap the bottom small end so I can use a SHCS and washer so the 'scope cannot fall off the bottom end.

-I need to make some camera mounts and tubes to fit a camera to the third port

-brino