On the front of the part that moves in Y, the top of the saddle, it appears as if there are 'way wipers' screwed to the face. Remove those screws, the wipers will come off. Under one of them, beside the dovetail, expect to find a 3/4" diameter piece with a big screwdriver slot in it. screw that tight, well, snug, anyway, and see if that takes care of the slop. If so, adjust it so you can feel the drag but the table won't move when you try to rock it. When done, put the 'way wipers' and their screws back on.

Nice find, nice lot of tooling, too.

vise

vise

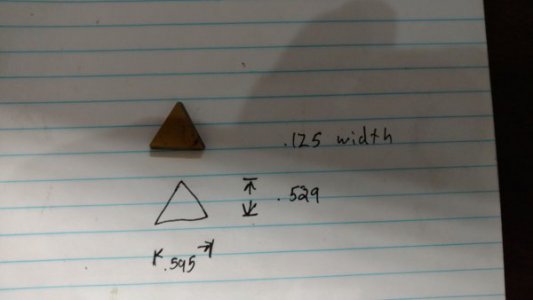

tooling

tooling

It been a really weird month for me, after the 6913 lathe this thing came into my life. I don't have it here yet but I do have the receipt for purchase. 2000.00. Just like the lathe questions I had, what do you guys see here as far as what it is, quality, does it look like anything is missing? I got it all from a machine shop here in town that was selling it. Hoping to get it here tomorrow if I can convince my hired man to let me leave and go get it!

It been a really weird month for me, after the 6913 lathe this thing came into my life. I don't have it here yet but I do have the receipt for purchase. 2000.00. Just like the lathe questions I had, what do you guys see here as far as what it is, quality, does it look like anything is missing? I got it all from a machine shop here in town that was selling it. Hoping to get it here tomorrow if I can convince my hired man to let me leave and go get it!