- Joined

- Dec 18, 2016

- Messages

- 3

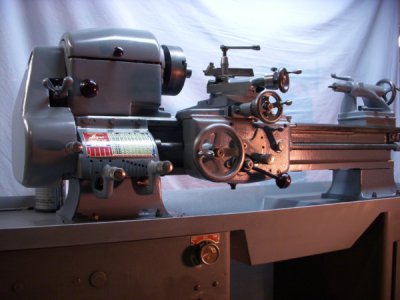

Guys, I just picked up this logan 825 in chicago for 450... its got some issues, it didn't come with a chuck and it's reverse gear handle has been broken off.

I saw a reverse gear bracket on ebay, but it's off a Logan 200, do the parts interchange on these 10" logans. I don't know how different these are.

Also, the ways look really good except for right by the headstock. what do you guys think about this?

And finally I know I have to get my hands on a chuck at some point. I could use some advise in that area as well, I'm just beginning, so I don't really want to spend a lot. But I want something that will work.

I'm thinking of restoring this machine, at least going through it and making sure nothing is really bad on it, maybe throw a coat of paint on it. The leads screw looks real good, but I haven't even gotten into the transmission yet. Do you guys think this is a good candidate to fix up?

I saw a reverse gear bracket on ebay, but it's off a Logan 200, do the parts interchange on these 10" logans. I don't know how different these are.

Also, the ways look really good except for right by the headstock. what do you guys think about this?

And finally I know I have to get my hands on a chuck at some point. I could use some advise in that area as well, I'm just beginning, so I don't really want to spend a lot. But I want something that will work.

I'm thinking of restoring this machine, at least going through it and making sure nothing is really bad on it, maybe throw a coat of paint on it. The leads screw looks real good, but I haven't even gotten into the transmission yet. Do you guys think this is a good candidate to fix up?