- Joined

- Sep 10, 2013

- Messages

- 9

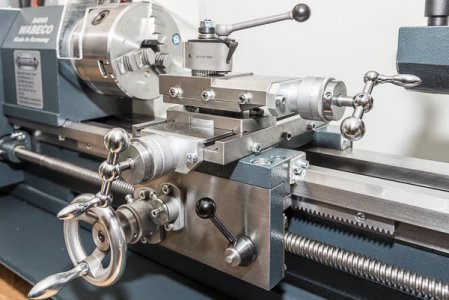

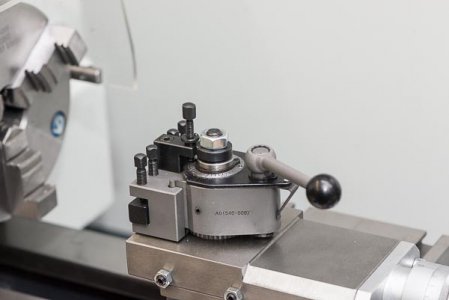

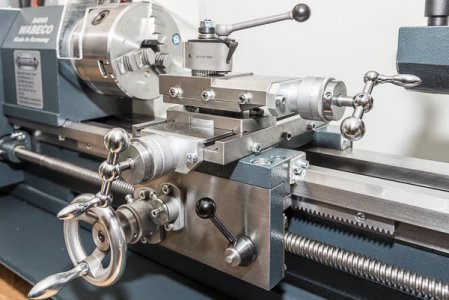

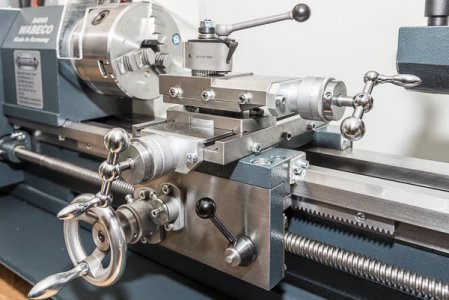

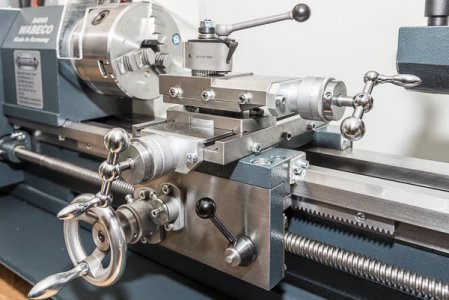

I just acquired a new lathe, a Wabeco D4000E, for turning small parts in my prototyping business. It's basically a beefed up mini lathe (8x14, 2HP, 160lbs), it's "Made in Germany", and the make and quality is fantastic.

In Europe the availability of machinery, new or used, is not nearly as varied as in the US, and consequently a decent quality rebranded import mini lathe is almost $2000. The Wabeco is approx. $3000 so that makes it a very attractive alternative.

Some pictures since these don't show up that often:

I put a few more words on it here: http://blog.offcuts.dk/2014/01/06/new-lathe-wabeco-d4000e/

In Europe the availability of machinery, new or used, is not nearly as varied as in the US, and consequently a decent quality rebranded import mini lathe is almost $2000. The Wabeco is approx. $3000 so that makes it a very attractive alternative.

Some pictures since these don't show up that often:

I put a few more words on it here: http://blog.offcuts.dk/2014/01/06/new-lathe-wabeco-d4000e/