B

Buffalo20

Forum Guest

Register Today

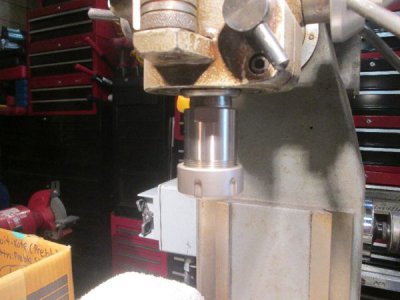

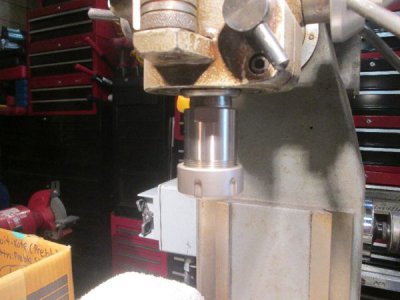

Tuesday of this past week, I received, from LMS, my new ER32 x R8 collet chuck (LMS# 5449). The chuck is very well made and has almost unmeasurable runout. I bought this for the Rockwell milling machine, the other 2 mills, use the Din 6388 style collets and collet chuck, but I had numerous ER32 collets,so this seemed acceptable option. With the 2 quick jobs I did this week, so far I really like it.

I did have to perform a slight modification to the collet chuck, I drilled a 1/4" hole in the shank of the chuck. This, so I can use a pin spanner wrench to tighten/loosen the collet nut. I find it much easier to tighten/loosen the collet nut, when the 2 wrenches are next to each other, With the nerve damage to the arm and the repeated rotator-cuff operations, it seems to put the least amount of stress on the body (shoulder).

I also put the reflective tach tape, then covered by a strip of clear packaging tape.

1 - the collet chuck

2 - in the mill

3 - the hole and the reflective tape

4 - using the wrenches

5 - the wrenchesView attachment 235255 View attachment 235256 View attachment 235257

I did have to perform a slight modification to the collet chuck, I drilled a 1/4" hole in the shank of the chuck. This, so I can use a pin spanner wrench to tighten/loosen the collet nut. I find it much easier to tighten/loosen the collet nut, when the 2 wrenches are next to each other, With the nerve damage to the arm and the repeated rotator-cuff operations, it seems to put the least amount of stress on the body (shoulder).

I also put the reflective tach tape, then covered by a strip of clear packaging tape.

1 - the collet chuck

2 - in the mill

3 - the hole and the reflective tape

4 - using the wrenches

5 - the wrenchesView attachment 235255 View attachment 235256 View attachment 235257

Last edited by a moderator: