- Joined

- Jun 22, 2015

- Messages

- 68

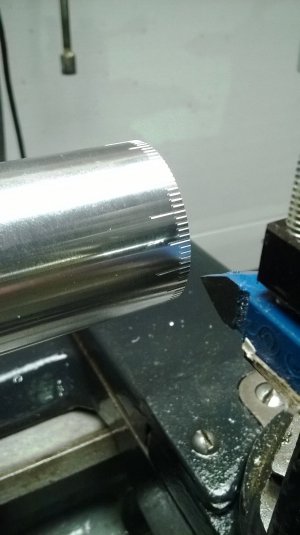

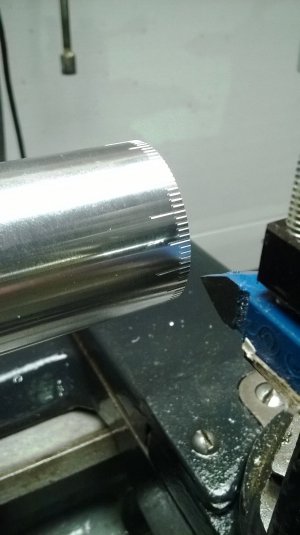

I just made a couple of new dials for my Logan lathe. The difference this made is amazing... the original are almost unusable (at least for old eyes). Tubalcain on Youtube has a video on how to do this although I did mine slightly different. I kept the old dial and made the new dial slip over the old one. Tubalcain's version replaced the dial. I was a little worried about the aluminum dial taking the thrust of the compound when you make adjustments. Leaving the steel dials in place seemed to be a good option. A piece of nylon under the set screw makes setting the dial to zero very easy. One other thing I did different was I made my dials smaller than Tuabalcain. While the larger dial would be better it would also limits the travel of my cross slide. 1-3/8" is still WAY better than 7/8"

The process involved threading and arbor (threading was a new adventure), mounting it to the outboard side of my lathe spindle. The saw blade was for indexing and I mounted a lathe tool sideways to scribe the lines.

The process involved threading and arbor (threading was a new adventure), mounting it to the outboard side of my lathe spindle. The saw blade was for indexing and I mounted a lathe tool sideways to scribe the lines.