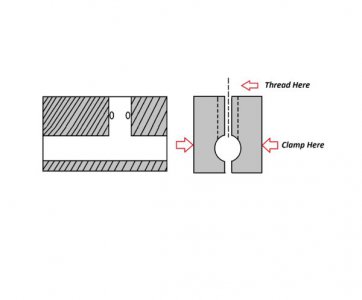

I would like to take this tie rod end and turn down the thread shank then cut new threads....

not quite sure how to go about setting this up in my lathe .... Anyone have any ideas ? best way to tackle this...

I thought about making 3 small spacers and chucking it in my 3 jaw..... Just don't want to eat one of them if it something goes wrong...

not quite sure how to go about setting this up in my lathe .... Anyone have any ideas ? best way to tackle this...

I thought about making 3 small spacers and chucking it in my 3 jaw..... Just don't want to eat one of them if it something goes wrong...