- Joined

- Sep 7, 2015

- Messages

- 16

That is where I purchased my tinplate. The site has a lot of great information on working with that stuff too. A nice resource, indeed!

My idea for the rivets was to tin the metal and then go over the cooled surface with the tip of the iron making little raised solder bumps. Too much heat/time and they'll flatten out, too quick and they'll be pointy like Hershey kisses (which I'd soften with a little sanding or Dremel wire brush for uniformity). Just an idea... wear a mask for that!

And I often marvel at what was accomplished with "crude" methods a few 100 years ago. I've read some brilliantly clever methods of machining and layout in some of the old handbooks that have long been cast aside and forgotten.

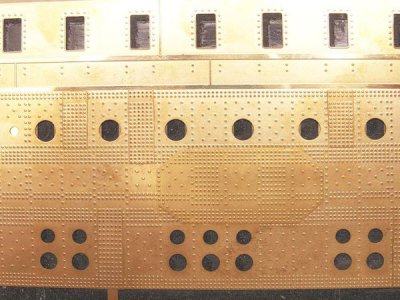

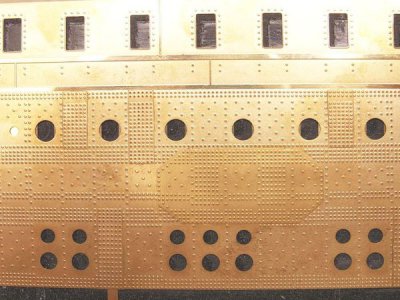

Ain't this beautiful though?

What about drilling a SMALL HOLE & INSERTING A STRAIGHT PIN HEAD & THEN SOLDER ON THE INSIDE

I don't have a pin handy,but I don't think they have flat bottoms on their heads,and thus would not snug up flat against the ship's hull. And,they would be too large anyway,unless you were building a pretty large model,several feet long.

Here's a hint: Don't float your model Titanic in the bath tub. It might sink!!

Here is an idea. Drill small depressions in your plate to accept micro ball bearings. Drop the ball in the depression and fix with glue or solder. Drilling the depressions gives you the advantage of being able to perfectly place the locations of the faux rivets on your model. You have not given dimensions for the rivet heads but this source has brass balls as small as .2mm which, at your 1:144 scale would be just over an inch.That is likely how I'd do it if that didn't call for thousands of such rivets. I'm just not determined enough to get that level of detail if it requires that much work. But that's a solid idea! Thanks.