I have a Atlas 3986 lathe which I want to wire to run in reverse to allow metric threading.

I have a Dayton 1/2 hp 100/220v reversible motor and a Dayton drum switch. I have read several threads here and elsewhere about this but do not see any the have the wiring connections to reverse I have on my motor.

Drum switch is a Dayton 2X441/RS-1

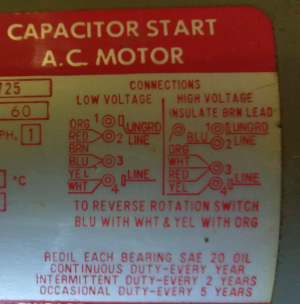

motor name plate;

Anybody have any ideas how to do this?

Most of the threads have one set of wires being reversed, the name plate has two.

to reverse rotation switch blu with wht & yel with org

How do you do that with a this drum switch?

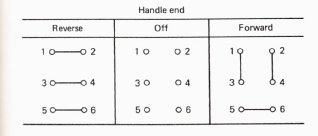

The drum switch internally is operates like this;

Any ideas how this would be done?

I have a Dayton 1/2 hp 100/220v reversible motor and a Dayton drum switch. I have read several threads here and elsewhere about this but do not see any the have the wiring connections to reverse I have on my motor.

Drum switch is a Dayton 2X441/RS-1

motor name plate;

Anybody have any ideas how to do this?

Most of the threads have one set of wires being reversed, the name plate has two.

to reverse rotation switch blu with wht & yel with org

How do you do that with a this drum switch?

The drum switch internally is operates like this;

Any ideas how this would be done?