- Joined

- Dec 16, 2015

- Messages

- 51

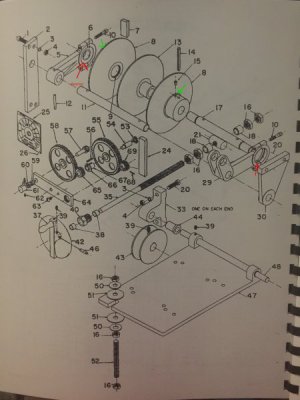

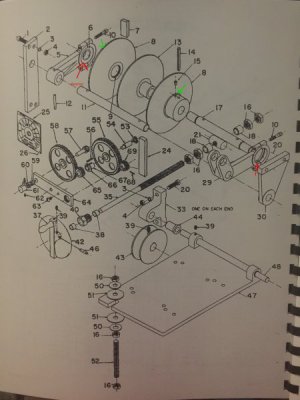

Ok so I got new bearings from Scott and I gotta say I'm pretty sure he overnighted them to me, so thanks for that Scott, so I removed the pulley (jack shaft) and slid the old bearings off and went to put the new ones on I then noticed the little grease cup, so I opened it, it was full of blacknpowder! I blew it all out and opened the set screw on the other side, I blew it out, everything seems fine I don't know how long it's been since this was oiled unless the black powder was some sort of graphite. Nothing feels worn and the center pulley still slides back and forth fine, does anyone know what to put back in these holes for lubrication, I don't want to put the wrong thing in, oil seems like it would somehow sling out and get on the belts.. Any help would be much appreciated

Last edited by a moderator: