-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need guidance cutting angles

- Thread starter Blackhawk

- Start date

- Joined

- Jun 17, 2012

- Messages

- 2,220

The video really makes it clear. Your tools are too big, that's #1. You can grind the crap out of the bottom hose huge cutters to get the bottom clearance you need. You can grind a small 1/4" HSS tool blank to get the angle. My preferred method and simplest is to use a 60 degree chamfer bit in the tail stock and drive the tailstock feed into the part. You didn't say how deep you had to go. Sometimes I'll just set the tool at the desired angle and drive it right straight back towards me, to the desired depth. A lot of ways to skin that cat. In all cases you need to grind the tool bottom to get that clearance. All cases except the chamfer tool in the tail stock. The only problem that can occur with the chamfer tool is chatter sometimes if your going too deep, but if you slow it way down and keep that barrel tight to the chuck jaws you should be fine.

The video really makes it clear. Your tools are too big, that's #1. You can grind the crap out of the bottom hose huge cutters to get the bottom clearance you need. You can grind a small 1/4" HSS tool blank to get the angle. My preferred method and simplest is to use a 60 degree chamfer bit in the tail stock and drive the tailstock feed into the part. You didn't say how deep you had to go. Sometimes I'll just set the tool at the desired angle and drive it right straight back towards me, to the desired depth. A lot of ways to skin that cat. In all cases you need to grind the tool bottom to get that clearance. All cases except the chamfer tool in the tail stock. The only problem that can occur with the chamfer tool is chatter sometimes if your going too deep, but if you slow it way down and keep that barrel tight to the chuck jaws you should be fine.

I have trouble hearing on this laptop. So he is cutting internal tapers? I agree with you he needs to either use a 1/4" HSS or 1/2" HSS that is heavily ground down on the bottom and sides to fit inside. I have used 1/2" bits since they are stronger in the past and turn the compound rest. He does do nice work.

B

Bill Gruby

Forum Guest

Register Today

- Joined

- Feb 19, 2013

- Messages

- 220

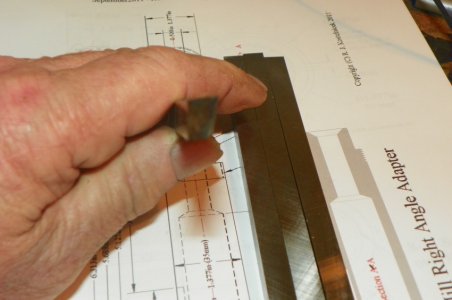

You may have to set your compound rest to 30 degrees with the adjusting screw toward the back of the lathe - 30 degrees from the part mounted in the lathe = grind a smallish 3/16 or 1/4 HSS toolbit and mount this in the QCTP. I had to turn my lathe backward so it would cut while turning counter-clockwise and advance the compound on this angle starting from the outside of the tube. then, crank the compound in as much as it will go and move cross slide toward the chuck a very small amount and advance the compound again until you have cut your chamfer. See the Tubalcain video showing how to cut tapers using the compound method. It will become clear.