Hi all,

I've got three 2-foot gauge kiln cars, one of which I'm going to turn into a locomotive for my railway. I've dissassembled them to clean out the gunk in the bearings, as they've been sitting for a decade in a farmer's field rusting away.

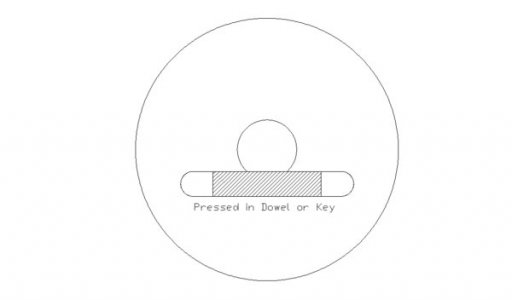

The problem I see, in turning one of them into a locomotive is the way the wheels are fitted to the axles. They are lightly pressed over an upset axle that has some gouges to friction hold it. In fact, they're so lightly pressed that I pulled the wheels off by hand. It's a spindle axle, meaning the whole thing turns.

The idea is to belt or chain drive the axles. The torque produced would likely make the wheels slip on their axles.

The first idea that came to mind is to create a keyway in the axle and wheel and key them all in place. I have a tiny hobby mill and a 9" SBA lathe and 2 drill presses. The axle could easily (I think?) be milled for the keyway but the wheel would be harder.

Perhaps the wheel could be mounted on the drill press and a broach could create the keyway by manually running it in and out (of course without any power to the DP).

A second idea I have instead of a keyway would be to turn some collars to fit on the insides of the wheels. Holes for set screws to the axle and then to the wheel could be drilled and tapped.

the wheels are just shy of a foot in diameter. The diameter of the axle is 1 3/8" and the hole in the wheel is about 3.5" deep.

Thanks for any ideas!

I've got three 2-foot gauge kiln cars, one of which I'm going to turn into a locomotive for my railway. I've dissassembled them to clean out the gunk in the bearings, as they've been sitting for a decade in a farmer's field rusting away.

The problem I see, in turning one of them into a locomotive is the way the wheels are fitted to the axles. They are lightly pressed over an upset axle that has some gouges to friction hold it. In fact, they're so lightly pressed that I pulled the wheels off by hand. It's a spindle axle, meaning the whole thing turns.

The idea is to belt or chain drive the axles. The torque produced would likely make the wheels slip on their axles.

The first idea that came to mind is to create a keyway in the axle and wheel and key them all in place. I have a tiny hobby mill and a 9" SBA lathe and 2 drill presses. The axle could easily (I think?) be milled for the keyway but the wheel would be harder.

Perhaps the wheel could be mounted on the drill press and a broach could create the keyway by manually running it in and out (of course without any power to the DP).

A second idea I have instead of a keyway would be to turn some collars to fit on the insides of the wheels. Holes for set screws to the axle and then to the wheel could be drilled and tapped.

the wheels are just shy of a foot in diameter. The diameter of the axle is 1 3/8" and the hole in the wheel is about 3.5" deep.

Thanks for any ideas!