- Joined

- May 29, 2014

- Messages

- 188

Here is the beginning of my new shop. It is being constructed in the external garage at our “new to us” home in Delaware. The garage originally was approximately 31ft wide and 27ft deep with 11ft ceilings. I divided it into a 17 by 27 shop and a 14 by 27 garage. The shop is now fully insulated and I installed a 15K BTU heat-pump for climate control (shop bay only). There was 100amp electrical already in place. The drywall is nearly completed, and it will be painted white inside. I am going to install 3 dual tube 8ft fluorescent fixtures in the ceiling and 2 dual tube 4ft fluorescent fixtures on the walls near the garage door. A ceiling fan will also be installed. I created a “lifting eye” in the ceiling near the center which goes through a 4x6 beam that is lag bolted to the top of the rafters. I installed lots of outlets (both 110v & 220v) throughout the shop. I still need to insulate the garage door (10ft wide by 9ft high), and fabricate a 4ft by 7ft sliding door to go between the two bays. The previous homeowner left a very large & heavy work bench in the structure. It will only need minimal upgrading to be totally functional.

Now for the goodies.

My PM932PDF mill (with DRO) is on site awaiting its’ new home. The PM12x36 is somewhere between here & China (I hope). I have my TIG already set up, and have used it to fab the base for the PM932 (shown below), and the wall brackets for the external portion of the heat-pump. My air compressor is a Porter Cable 60 gal—It is pretty loud, and may remain in the garage bay—haven’t gotten that figured out yet. My MIG & Plasma remain to be set up. I obtained one of the 4x6 band saws the other day and it, too is ready to go.

OK, a few pics: The first few are just the interior of the original garage and then a couple with the drywall nearly completed.

A little farther along in the project.

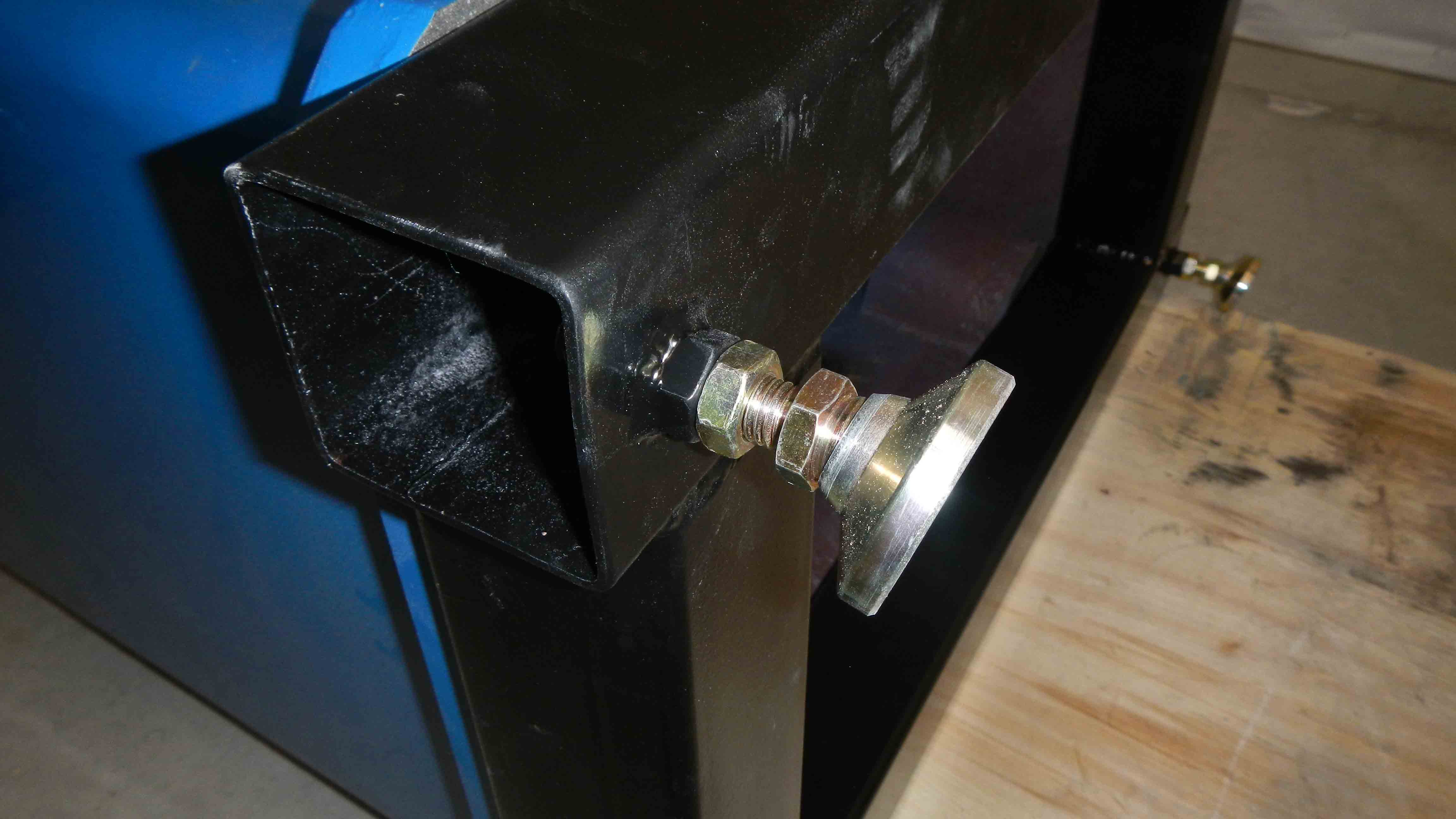

Base for the PM932PDF. It is 3in square tubing approx. .100 thick. I used ½ bolts to secure it to the base of the mill. I purchased the leveling feet on AMAZON. (Copy the link into your browser.)

http://www.amazon.com/Level--Diamet...e=UTF8&qid=1428069383&sr=8-2&keywords=levelit

They are also ½ inch and allow approx. 1 ½inch of vertical adjustment. I drilled a ½ hole in the bottom of the tubes and then TIGed on a ½ inch nut for the adjusters to screw into. In the end, the new base allows for 4 ½ to 6 inches of additional height for the mill.

Well, that about covers it for now. More drywall mud to spread.

Jerry in LSD (Lower Slower Delaware)

Now for the goodies.

My PM932PDF mill (with DRO) is on site awaiting its’ new home. The PM12x36 is somewhere between here & China (I hope). I have my TIG already set up, and have used it to fab the base for the PM932 (shown below), and the wall brackets for the external portion of the heat-pump. My air compressor is a Porter Cable 60 gal—It is pretty loud, and may remain in the garage bay—haven’t gotten that figured out yet. My MIG & Plasma remain to be set up. I obtained one of the 4x6 band saws the other day and it, too is ready to go.

OK, a few pics: The first few are just the interior of the original garage and then a couple with the drywall nearly completed.

A little farther along in the project.

Base for the PM932PDF. It is 3in square tubing approx. .100 thick. I used ½ bolts to secure it to the base of the mill. I purchased the leveling feet on AMAZON. (Copy the link into your browser.)

http://www.amazon.com/Level--Diamet...e=UTF8&qid=1428069383&sr=8-2&keywords=levelit

They are also ½ inch and allow approx. 1 ½inch of vertical adjustment. I drilled a ½ hole in the bottom of the tubes and then TIGed on a ½ inch nut for the adjusters to screw into. In the end, the new base allows for 4 ½ to 6 inches of additional height for the mill.

Well, that about covers it for now. More drywall mud to spread.

Jerry in LSD (Lower Slower Delaware)