- Joined

- Jun 26, 2014

- Messages

- 619

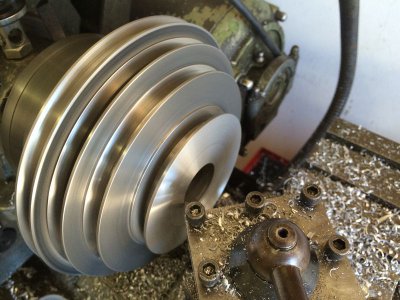

Well I purchased my first milling machine a week ago to go with the small lathe in the garage.

It's a CME (Spanish) F-900 horizontal mill with a vertical milling head attachment (also CME I assume). Unfortunately didn't come with the rotary table and divider in the photo.

Was in reasonable order and not actually in need of any work, but as we had to dismantle it to get it into bits two people could handle loading for the move home (it is a solid cast iron body) it is now in pieces in the garage so I thought I may as well give it a good cleanup and a look over all the parts before reassenbling it. Of course if it's in parts and clean already I might as well give it a repaint too - all probably totally unnessary but if I don't do it now I know I probably won't bother to pull it apart to do it once it's working.

So far haven't found any major issues. One shaft on the saddle is quite scored where the lock engagaes (the lock was probably sticking and not fully disengaged during use) but I think I will just leave it as is. And the coolant tray had a split at the corner which I welded up before painting.

Had some difficulty removing a roll pin pinning a gear to a shaft but after turning up a suitably size tool on the lathe and some rudimentary hardening (through it in the BBQ coals while cooking dinner last night and when it was red hot dropped it in a bucket of water) managed to knock it out.

Will post some photos as it goes if people are interested.

p.s. if anyone else has one of these and has a manual I would be interested in a copy. Can't seem to find any info on it on the internet.

Peter

It's a CME (Spanish) F-900 horizontal mill with a vertical milling head attachment (also CME I assume). Unfortunately didn't come with the rotary table and divider in the photo.

Was in reasonable order and not actually in need of any work, but as we had to dismantle it to get it into bits two people could handle loading for the move home (it is a solid cast iron body) it is now in pieces in the garage so I thought I may as well give it a good cleanup and a look over all the parts before reassenbling it. Of course if it's in parts and clean already I might as well give it a repaint too - all probably totally unnessary but if I don't do it now I know I probably won't bother to pull it apart to do it once it's working.

So far haven't found any major issues. One shaft on the saddle is quite scored where the lock engagaes (the lock was probably sticking and not fully disengaged during use) but I think I will just leave it as is. And the coolant tray had a split at the corner which I welded up before painting.

Had some difficulty removing a roll pin pinning a gear to a shaft but after turning up a suitably size tool on the lathe and some rudimentary hardening (through it in the BBQ coals while cooking dinner last night and when it was red hot dropped it in a bucket of water) managed to knock it out.

Will post some photos as it goes if people are interested.

p.s. if anyone else has one of these and has a manual I would be interested in a copy. Can't seem to find any info on it on the internet.

Peter