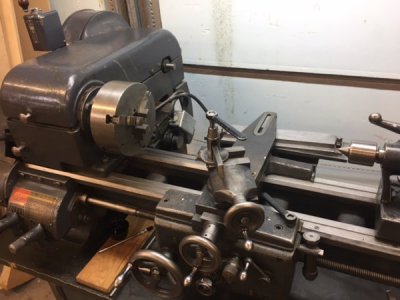

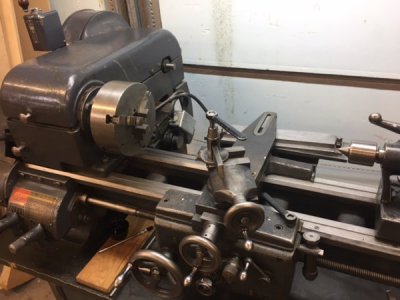

This is my first lathe, and I have no training other than from books, videos and great forums like this one. I fell into this one several years ago when a friend's father passed. She ended up with it when all was divided up, but had no interest and it sat disassembled for quite a few years. I always wanted one, so I expressed interest and we made a deal.

It was made in 1948 according to the serial number. It was a bench model, and someone put a home made base and kinda ugly chip pan on it. I don't know what they used for a motor support, but I'm using a 4x4. It came with three chucks - a 6 inch Westcott three jaw and an 8 inch Westcott four jaw (which I though was cool since that's my name, no relation so far as I know) and a brand new in the box 6 inch Craftsman four jaw. There were a ton of 1/4 tool bits, most ground but some new, as well as a lot of 3/16" and 1/2" bits. There were a left, right, and straight tool holders for the lantern post, all for 1/4", I have no idea why he had all the 1/2" ones, and about four or five cutoff tool holders, a Jacobs chuck and a live center, several dial indicators and holders, and some stuff I'm still working on identifying.

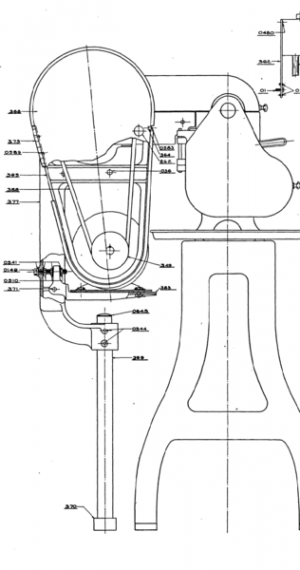

No steady or follower rests or boring bar holders, but there was most of a partly home made taper attachment I'm working on (posted on the main part of the forum).

It seems to have been used a lot but not abused, and in my attempts at checking the accuracy, it seems OK. The leather belt was stretched and unusable, so I tried an automotive serpentine belt. The glue method didn't work, so I laced it with high end Kevlar fishing line. That worked until the line rotted away. The belt squeals, so I tried squirting some belt dressing on it. Bad idea, I think it melted my fishing line. I replaced the line with some small stainless steel wire, which is really ugly but seems to be holding.

It was made in 1948 according to the serial number. It was a bench model, and someone put a home made base and kinda ugly chip pan on it. I don't know what they used for a motor support, but I'm using a 4x4. It came with three chucks - a 6 inch Westcott three jaw and an 8 inch Westcott four jaw (which I though was cool since that's my name, no relation so far as I know) and a brand new in the box 6 inch Craftsman four jaw. There were a ton of 1/4 tool bits, most ground but some new, as well as a lot of 3/16" and 1/2" bits. There were a left, right, and straight tool holders for the lantern post, all for 1/4", I have no idea why he had all the 1/2" ones, and about four or five cutoff tool holders, a Jacobs chuck and a live center, several dial indicators and holders, and some stuff I'm still working on identifying.

No steady or follower rests or boring bar holders, but there was most of a partly home made taper attachment I'm working on (posted on the main part of the forum).

It seems to have been used a lot but not abused, and in my attempts at checking the accuracy, it seems OK. The leather belt was stretched and unusable, so I tried an automotive serpentine belt. The glue method didn't work, so I laced it with high end Kevlar fishing line. That worked until the line rotted away. The belt squeals, so I tried squirting some belt dressing on it. Bad idea, I think it melted my fishing line. I replaced the line with some small stainless steel wire, which is really ugly but seems to be holding.