- Joined

- Jan 22, 2014

- Messages

- 578

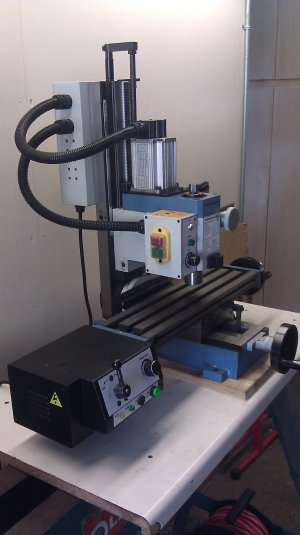

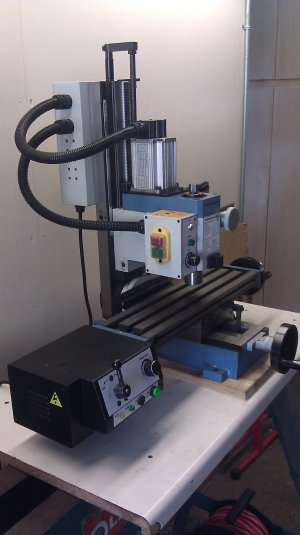

I decided to finally post the mods I made on my LMS Mill, even though it's a few year old now.

I ordered my mill with the power feed they offer, and installed it upon unpacking. I've been more than happy with the performance and I use it whenever I have the chance. It is a bit pricey, but I think that it's worth the cost unless you plan on going CNC in the future.

I also did the air spring conversion to get rid of the cumbersome torsion spring and make room for the DRO. It is also a great mod, very easy, reliable, clean and affordable.

I also purchased the LMS rotary table and 3-jaw chuck and my only complaint is the depth it robs from the Z axis. While I had my mill apart, I did some R&D to see if I could find another few inches of Z axis because I've run out of room in the past trying to change out the drill/R8 collet with the rotary table/3 jaw. I discovered that an additional 1" is an easy task, but 2" are possible with a few more extensive mods. I'm still researching my options there, but I'll post it if/when I do it.

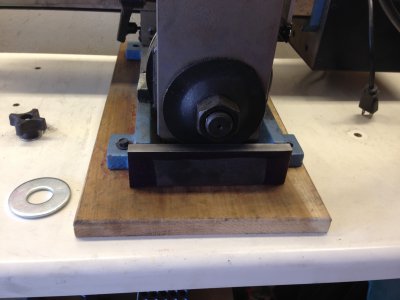

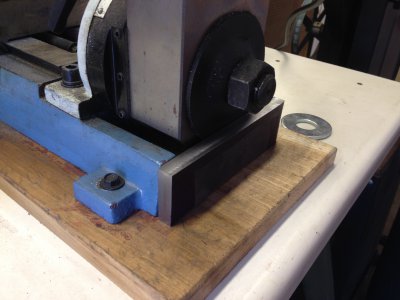

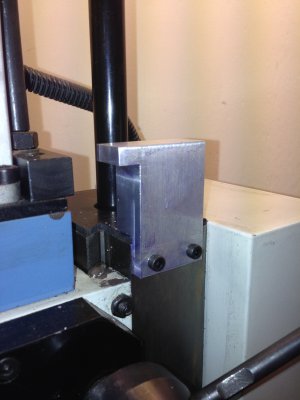

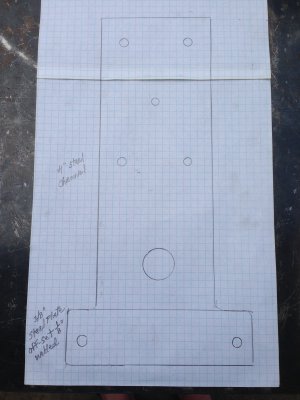

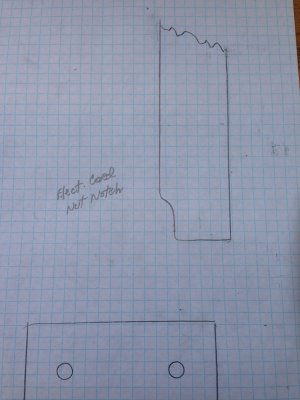

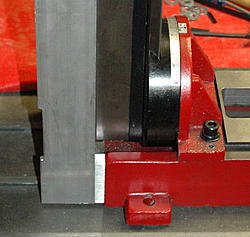

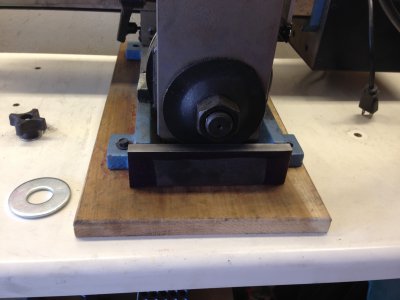

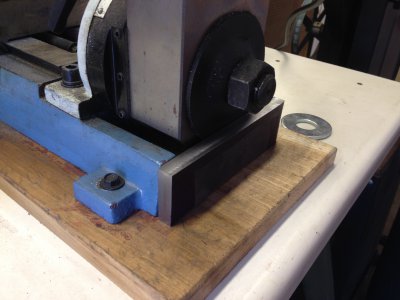

I then found that I got some chatter when trying to cut anything over .020" steel. I researched a lot of threads and found that the remedy was to add a stiffening bracket to the column. There were as many designs on the web as people posting them and so this is the design I came up with. 4" steel channel on a piece of 3/8" steel plate. Welded, drilled and mounted to the back of the column and then trammed. I read where some others were experiencing "head drop" and I found that I had to take a bit off the mill base because it wasn't let the new plate seat properly. After I did that, it trammed out fine.

Note: Most of the threads on this subject are centered around the similar Sieg model and not the LMS. The Sieg column is designed/mounted differently in the base (or vice versa) than the LMS. In other words, the LMS column is set back inside the base by 1/8" and the Sieg is set out by about the same amount. Here are some pics of my bracket.

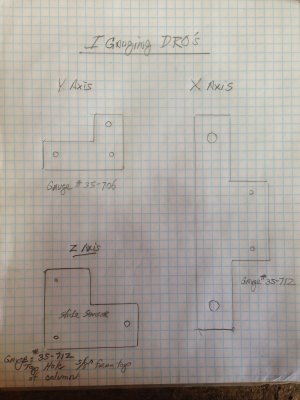

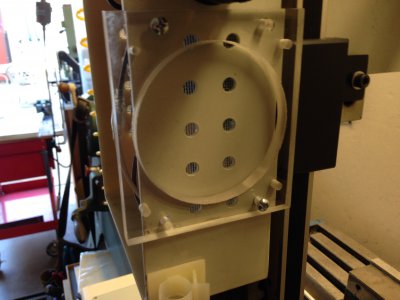

I also mounted the I Gaging DROs from Grizzly to all 3 axis and here some pics of my mod. Nothing to notable here other than I don't know I waited so long. I just recently installed them when they've been sitting around the garage for over a year now. It was after my last project (Elmer's #15) that I promised myself I'd get them done before starting any other projects.

I ordered my mill with the power feed they offer, and installed it upon unpacking. I've been more than happy with the performance and I use it whenever I have the chance. It is a bit pricey, but I think that it's worth the cost unless you plan on going CNC in the future.

I also did the air spring conversion to get rid of the cumbersome torsion spring and make room for the DRO. It is also a great mod, very easy, reliable, clean and affordable.

I also purchased the LMS rotary table and 3-jaw chuck and my only complaint is the depth it robs from the Z axis. While I had my mill apart, I did some R&D to see if I could find another few inches of Z axis because I've run out of room in the past trying to change out the drill/R8 collet with the rotary table/3 jaw. I discovered that an additional 1" is an easy task, but 2" are possible with a few more extensive mods. I'm still researching my options there, but I'll post it if/when I do it.

I then found that I got some chatter when trying to cut anything over .020" steel. I researched a lot of threads and found that the remedy was to add a stiffening bracket to the column. There were as many designs on the web as people posting them and so this is the design I came up with. 4" steel channel on a piece of 3/8" steel plate. Welded, drilled and mounted to the back of the column and then trammed. I read where some others were experiencing "head drop" and I found that I had to take a bit off the mill base because it wasn't let the new plate seat properly. After I did that, it trammed out fine.

Note: Most of the threads on this subject are centered around the similar Sieg model and not the LMS. The Sieg column is designed/mounted differently in the base (or vice versa) than the LMS. In other words, the LMS column is set back inside the base by 1/8" and the Sieg is set out by about the same amount. Here are some pics of my bracket.

I also mounted the I Gaging DROs from Grizzly to all 3 axis and here some pics of my mod. Nothing to notable here other than I don't know I waited so long. I just recently installed them when they've been sitting around the garage for over a year now. It was after my last project (Elmer's #15) that I promised myself I'd get them done before starting any other projects.