So I have always wanted to be able to work metal and cut and shape it to what I wanted it to be, and I now can. So I figured I would share my first learning project with you all. I was able to get my hands on a Veron Vertical Jig Borer/Milling machine, I think it was manufactured in 1932. Simple machine with not a ton of feature, but I think it is a good starting machine for me. First here is a quick picture of my machine. This is where it sat before I got it home to my garage last month.

Before I got it home I think that it sat for a number of years only getting rarely used and no maintenance, due to the age of the previous owner. Because of this it was in some need of some TLC. I had to rewire the motor, previous owner didn't remember if it was 120 or 220. But it didn't matter the power cord was old and brittle, so I replaced it to be safe. I also replace the belts and am slowly getting the machine re-oiled up, think I have all the oil points finally.

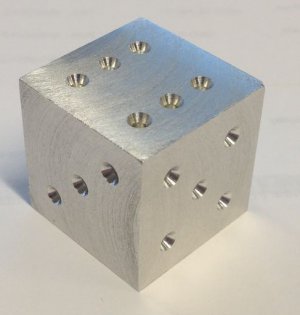

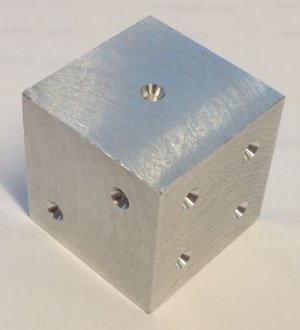

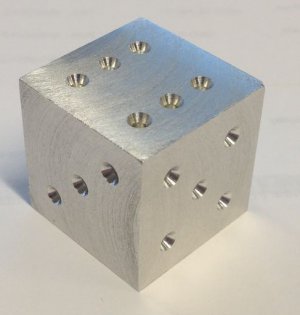

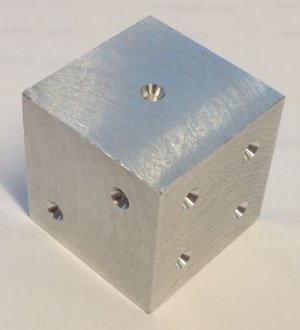

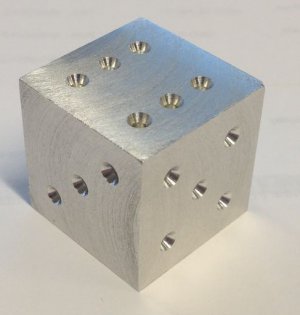

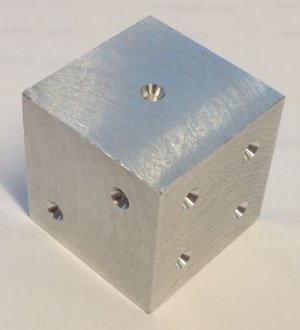

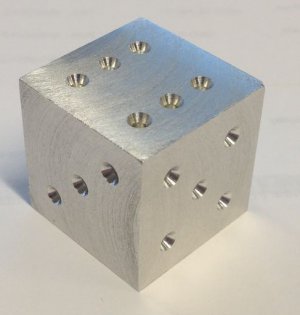

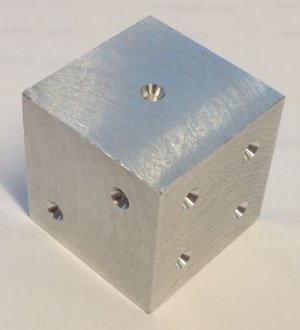

Now a couple pictures of my first project. Nothing fancy here, but it turned out to be a great learning project, more so than I figured it would.

Started this just to cut something on the machine and this is what it became as I played. This is a 1" square cube that was then dimpled with the markings to be a dice. This started as a chunk of aluminum that was 1.7 or larger all the way around. This turned out to be a good project as I was able to use most parts of the machine. From measuring thickness of the stock and only cutting the right amount to get the 1" dimension all the way around. Using the tables to then move the piece around to position it to drill for the marks. Learned a lot about feed rates and how that impacts the finish, to reading the dial gauges that the milling machine has for precious placement. I have a better idea on how to get back-lash out of this machine, and it has a lot, one table has almost 50 thou of backlash. Learned to clamping the work tightly ( that was a scaring one, made me jump a little ). I still have a long way to go though.

I have enjoyed this little project and can't wait to do more. Now that this one is up and running going to turn my attention to the Atlas lathe that needs a good cleaning. Watch for more projects in the future. )

)

Philip

Before I got it home I think that it sat for a number of years only getting rarely used and no maintenance, due to the age of the previous owner. Because of this it was in some need of some TLC. I had to rewire the motor, previous owner didn't remember if it was 120 or 220. But it didn't matter the power cord was old and brittle, so I replaced it to be safe. I also replace the belts and am slowly getting the machine re-oiled up, think I have all the oil points finally.

Now a couple pictures of my first project. Nothing fancy here, but it turned out to be a great learning project, more so than I figured it would.

Started this just to cut something on the machine and this is what it became as I played. This is a 1" square cube that was then dimpled with the markings to be a dice. This started as a chunk of aluminum that was 1.7 or larger all the way around. This turned out to be a good project as I was able to use most parts of the machine. From measuring thickness of the stock and only cutting the right amount to get the 1" dimension all the way around. Using the tables to then move the piece around to position it to drill for the marks. Learned a lot about feed rates and how that impacts the finish, to reading the dial gauges that the milling machine has for precious placement. I have a better idea on how to get back-lash out of this machine, and it has a lot, one table has almost 50 thou of backlash. Learned to clamping the work tightly ( that was a scaring one, made me jump a little ). I still have a long way to go though.

I have enjoyed this little project and can't wait to do more. Now that this one is up and running going to turn my attention to the Atlas lathe that needs a good cleaning. Watch for more projects in the future.

Philip