- Joined

- Dec 15, 2015

- Messages

- 47

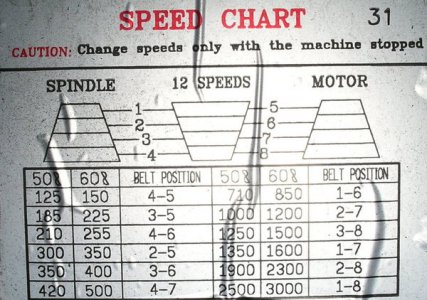

So i am looking for the front panel, and a pulley diagram for speeds.

and also gonna be fixing the broken hand wheels

Things left to do: clean it with something thinking brakeclean to start with

figure out a good way oil and get some fresh oil on it.

paint the base other then silver and get it setup on the base to cut something.

and also gonna be fixing the broken hand wheels

Things left to do: clean it with something thinking brakeclean to start with

figure out a good way oil and get some fresh oil on it.

paint the base other then silver and get it setup on the base to cut something.