Small update!

Aquiring a quick change tool post from my uncle this evening. Not sure what brand it is but I'm sure it will work for now.

Ordered a Chicago/latobe HSS drill bit set, South bend way oil, tap magic! Grabbing a few ounces of Mobile DTE24 (ISO32) oil from work.

I did some more checking and it appears my bearings might just have some absorbing cloth in them to hold oil. I thought it was grease at first but I was wrong.

I got the gear reduction broke loose/figured out! I didn't know what that lever did until Sunday!

The only thing I have left to de rust is the steady rest. will be done with everything then!

My drill chuck shows up Thursday. I should be able to start making my bushings so I can get to some threading!

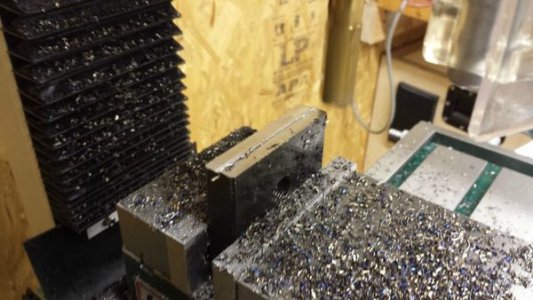

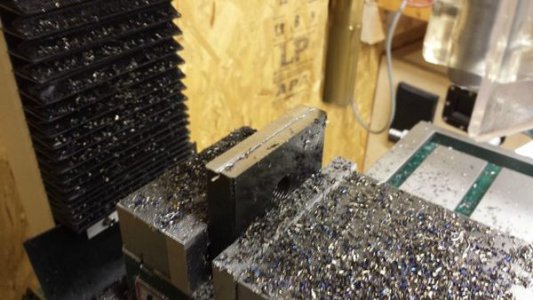

I think tonight will be cleaning and setting up the QCTP. I hope it works on there.

Ill get some pics.

Also I was thinking of adding a 36" Igauging digital readout on the lathe. What are your opinions? Will that decrease the value? I don't want to go ruining a nice piece of vintage equipment!

Aquiring a quick change tool post from my uncle this evening. Not sure what brand it is but I'm sure it will work for now.

Ordered a Chicago/latobe HSS drill bit set, South bend way oil, tap magic! Grabbing a few ounces of Mobile DTE24 (ISO32) oil from work.

I did some more checking and it appears my bearings might just have some absorbing cloth in them to hold oil. I thought it was grease at first but I was wrong.

I got the gear reduction broke loose/figured out! I didn't know what that lever did until Sunday!

The only thing I have left to de rust is the steady rest. will be done with everything then!

My drill chuck shows up Thursday. I should be able to start making my bushings so I can get to some threading!

I think tonight will be cleaning and setting up the QCTP. I hope it works on there.

Ill get some pics.

Also I was thinking of adding a 36" Igauging digital readout on the lathe. What are your opinions? Will that decrease the value? I don't want to go ruining a nice piece of vintage equipment!