- Joined

- Sep 10, 2014

- Messages

- 26

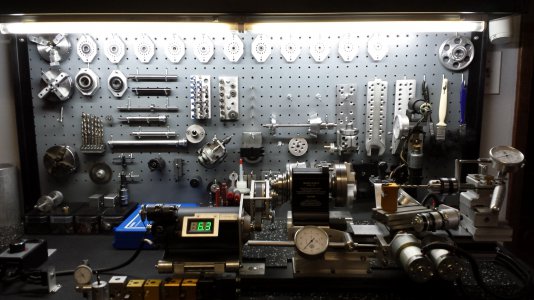

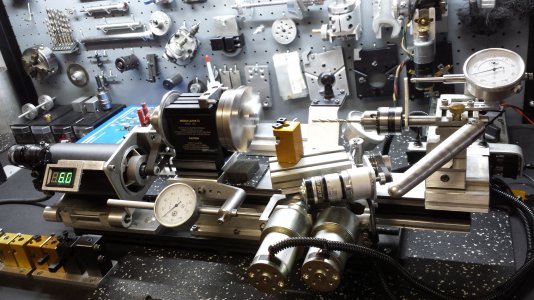

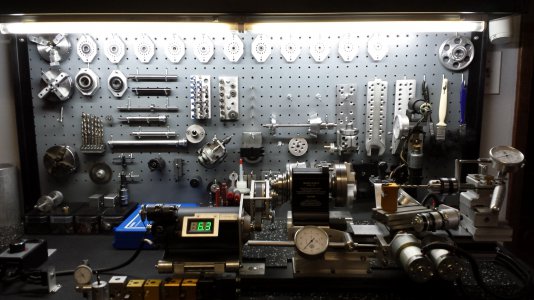

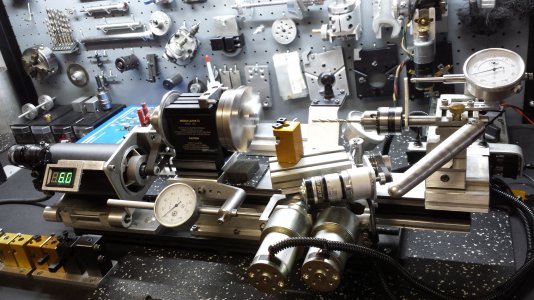

My Taig crown jewel - I have spent years modding these rigs

VIDEO = https://www.youtube.com/watch?v=WFO_kB_E6pM&feature=youtu.be

VIDEO = https://www.youtube.com/watch?v=WFO_kB_E6pM&feature=youtu.be

Last edited: