- Joined

- Jul 9, 2014

- Messages

- 613

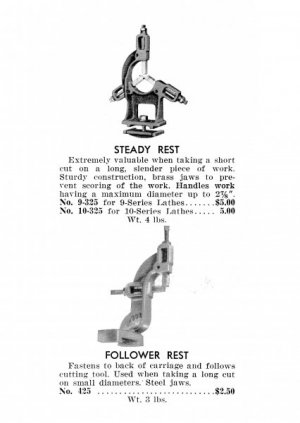

If any of you have a moving steady fitted to your Atlas lathes would you be so kind and take several different angled pictures of it including some from the rear of the lathe looking almost level with the saddle area when standing by the motor and post it in this thread please .

My reason for asking is I've got hold of a set of old but pristine unused moving & fixed steadies without any mounting plates etc . , unfortunately they are for a slightly smaller 8 inch throw lathe .( Mines a 10 inch throw ) .

I've sorted out / drawn up the fixed steady arrangement and found suitable measurements for things .

I want to try and work out how /where the moving steady should be mounted as I'll have to fabricate my own mountings .

My reason for asking is I've got hold of a set of old but pristine unused moving & fixed steadies without any mounting plates etc . , unfortunately they are for a slightly smaller 8 inch throw lathe .( Mines a 10 inch throw ) .

I've sorted out / drawn up the fixed steady arrangement and found suitable measurements for things .

I want to try and work out how /where the moving steady should be mounted as I'll have to fabricate my own mountings .