- Joined

- Jan 2, 2014

- Messages

- 9,241

I've done alright using a bench grinder in the past for shaping my lathe tools, but I wanted to try @mikey's method he posted about here:

http://www.hobby-machinist.com/threads/models-for-grinding-hss-lathe-tools.62111/post-511692

The problem is that my current bench sander doesn't let me get anywhere near the edge of the sanding disc or belt.

It won't allow doing the top face of the lathe tool like @mikey shows:

(used without permission from page 4 of Mikey's thread here: http://www.hobby-machinist.com/threads/models-for-grinding-hss-lathe-tools.62111/post-514226)

My machine is a Mastercraft 55-3554-4 120V, 6A, 4x36" belt and 8" disc sander.

Despite the make, it's been....well.....okay........ignoring the fact that you may need to spin the belt by hand to get it to start spinning rather than sitting there and humming.

Here's the machine:

(sorry the background is so "busy".........I have a way too much crammed into my 20'x20' garage!)

Here's the disc sander:

the table does tilt down, but the disc is recessed in that ring.

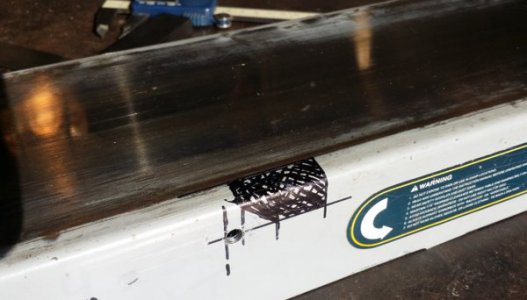

and the edge of the belt:

so again I cannot get anywhere near it........unless.......

the frame is pretty thick......

If I could remove some material in this area:

then I could use the very edge of the belt!

Here it is set up on the mill:

those clamps are directly over the three cross supports in the c-shaped frame.

the drive shaft is in the t-slot.

First cut:

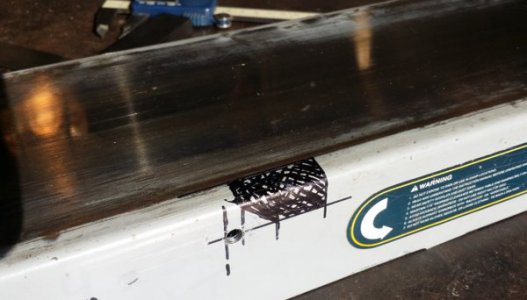

...and done:

ready to use with the little table installed:

It worked great!

The frame is still plenty strong.....and I was able to try Mikey's method of shaping lathe tools.

I'll post those results in that thread.......

-brino

By the way, the newer model of that sander here: http://www.canadiantire.ca/en/pdp/mastercraft-belt-disc-sander-4-x-36-in-0553559p.html has the same part number but looks very different! The disc size is smaller 6" (instead of 8") and the unit seems to use more plastic.....so I don't know if my modifications would work on the newer model. Also the motor is now 4.3A (instead of 6A) and the manual says 1/2hp.

http://www.hobby-machinist.com/threads/models-for-grinding-hss-lathe-tools.62111/post-511692

The problem is that my current bench sander doesn't let me get anywhere near the edge of the sanding disc or belt.

It won't allow doing the top face of the lathe tool like @mikey shows:

(used without permission from page 4 of Mikey's thread here: http://www.hobby-machinist.com/threads/models-for-grinding-hss-lathe-tools.62111/post-514226)

My machine is a Mastercraft 55-3554-4 120V, 6A, 4x36" belt and 8" disc sander.

Despite the make, it's been....well.....okay........ignoring the fact that you may need to spin the belt by hand to get it to start spinning rather than sitting there and humming.

Here's the machine:

(sorry the background is so "busy".........I have a way too much crammed into my 20'x20' garage!)

Here's the disc sander:

the table does tilt down, but the disc is recessed in that ring.

and the edge of the belt:

so again I cannot get anywhere near it........unless.......

the frame is pretty thick......

If I could remove some material in this area:

then I could use the very edge of the belt!

Here it is set up on the mill:

those clamps are directly over the three cross supports in the c-shaped frame.

the drive shaft is in the t-slot.

First cut:

...and done:

ready to use with the little table installed:

It worked great!

The frame is still plenty strong.....and I was able to try Mikey's method of shaping lathe tools.

I'll post those results in that thread.......

-brino

By the way, the newer model of that sander here: http://www.canadiantire.ca/en/pdp/mastercraft-belt-disc-sander-4-x-36-in-0553559p.html has the same part number but looks very different! The disc size is smaller 6" (instead of 8") and the unit seems to use more plastic.....so I don't know if my modifications would work on the newer model. Also the motor is now 4.3A (instead of 6A) and the manual says 1/2hp.

,It's not the price that turns me off.

,It's not the price that turns me off.