- Joined

- Dec 20, 2012

- Messages

- 9,422

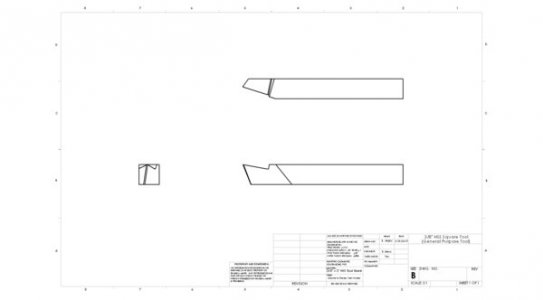

Thanks for sharing that with us Mike. I'll give he's strong consideration for the 2x72 I'm making.

It cuts like crazy on my little 2x42. I can only imagine what it would be like using a 1-2hp motor and having 72" of ceramic belt running around. It would probably take you just a few minutes to crank out a lathe tool.