-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Models for grinding HSS Lathe Tools

- Thread starter mikey

- Start date

- Joined

- Dec 22, 2015

- Messages

- 404

Thank you for the write-up on grinding these tools, Mike. Your articles and long posts are always informative and written in an easy-to-follow format, which I appreciate very much.

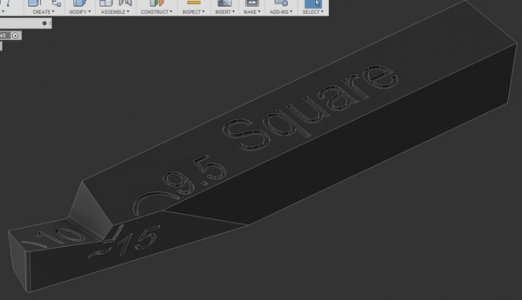

I can use this info to accurately model the samples you have ground for us so I can get the models to Metal for 3D printing.

Thanks again for all your work done for our benefit!

Randall

I can use this info to accurately model the samples you have ground for us so I can get the models to Metal for 3D printing.

Thanks again for all your work done for our benefit!

Randall

- Joined

- Aug 2, 2017

- Messages

- 23

I have been reading but not contributing. Could we get an update on the length of the waiting list? If it would be possible to add inside and outside radius tools, that would be great. Thank you for all the effort and great information.

Sent from my SM-G950U using Tapatalk

Sent from my SM-G950U using Tapatalk

- Joined

- Dec 20, 2012

- Messages

- 9,422

At this point, I realize I’m doing a complete brain dump on tool grinding. By the time I’m done with this you guys will know what I know about the subject. Some of you may be wondering what brought this on.

I suddenly lost my best friend a few years ago and it broke my heart. We were supposed to grow old together, going fishing and telling each other lies. He was a master cabinetmaker with so much to give, so much to teach but he never got the chance. Now I realize that none of us knows how much time we have; I’m not that old yet but my friend was 12 days younger than me so you never know. So I am passing on the information I have while I have the chance. I truly do appreciate the HM community and I cannot think of a better bunch of guys to pass this stuff to. If it helps you then I’ll be happy but I also hope it makes my friend happy to know that I did what he could not.

I suddenly lost my best friend a few years ago and it broke my heart. We were supposed to grow old together, going fishing and telling each other lies. He was a master cabinetmaker with so much to give, so much to teach but he never got the chance. Now I realize that none of us knows how much time we have; I’m not that old yet but my friend was 12 days younger than me so you never know. So I am passing on the information I have while I have the chance. I truly do appreciate the HM community and I cannot think of a better bunch of guys to pass this stuff to. If it helps you then I’ll be happy but I also hope it makes my friend happy to know that I did what he could not.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I have been reading but not contributing. Could we get an update on the length of the waiting list? If it would be possible to add inside and outside radius tools, that would be great. Thank you for all the effort and great information.

Sent from my SM-G950U using Tapatalk

Bryan, I'm sure @Z2V will be able to update you on the list. I don't know what you mean by inside and outside radius tools. Can you give us more info?

- Joined

- May 10, 2017

- Messages

- 1,199

I currently have fifteen people signed up. Mikey is making three sets so I have five names on each list. We are looking at probably about a week per person.

Bryan, send me PM and I'll get you added to to list.

Joe P, I have you down, I forgot to PM you confirmation,

Thanks to all

Jeff

Bryan, send me PM and I'll get you added to to list.

Joe P, I have you down, I forgot to PM you confirmation,

Thanks to all

Jeff

Last edited:

- Joined

- Sep 2, 2013

- Messages

- 54

I currently have fifteen people signed up. Mikey is making three sets so I have five names on search list. We are looking at probably about a week per person.

Bryan, send me PM and I'll get you added to to list.

Joe P, I have you down, I forgot to PM you confirmation,

Thanks to all

Jeff

Yep I got it, looking forward to it. Thanks.

Sent from my iPhone using Tapatalk

- Joined

- Aug 2, 2017

- Messages

- 23

I work in stainless. USDA requires 1/4 inch radius on machined parts for cleaning purposes. That requires a round headed cutter to eliminate 90 degree angles in cut. I grind the profiles off hand but suck at it. Hope the pics work out.Bryan, I'm sure @Z2V will be able to update you on the list. I don't know what you mean by inside and outside radius tools. Can you give us more info?

Sent from my SM-G950U using Tapatalk

- Joined

- Dec 20, 2012

- Messages

- 9,422

I work in stainless. USDA requires 1/4 inch radius on machined parts for cleaning purposes. That requires a round headed cutter to eliminate 90 degree angles in cut. I grind the profiles off hand but suck at it. Hope the pics work out.

Sent from my SM-G950U using Tapatalk

I can see the pics but only by replying. There is some info somewhere on the board that helps when posting pics with Tapatalk. Maybe they'll show up in this reply when I post it.

You are talking about form tools and the one you want has a huge contact point. In addition, you are working with stainless steel that is not particularly hard but can quickly become so when its worked. The problem we have here is that a form tool has no rake angles so we can't make it cut easier or reduce cutting temperatures. About all you have left are to try increasing the relief angle and maybe add back rake.

Here is what I would try. I would use a cobalt tool blank. Grind the tool to the shape you need but use a relief angle of about 13-15 degrees all around the tool's edge. I would give it about 10 degrees of back rake to start and see how it works. Keep your cutting speed low and keep the tool cutting continuously with a positive feed. If you're allowed, use sulfur-based cutting oil. I will admit that I haven't made a tool like this before but if I had to, this is where I would start.