- Joined

- Mar 15, 2015

- Messages

- 119

I'm just starting a long project to rebuild my mini excavator. The framework for the undercarriage is rusted out and has caused the front wheel fork to move around and eventually throw the track.

I have all the material now to do the rebuild and just parted 4 pieces of 3.5" 4340 for the front axle holders.

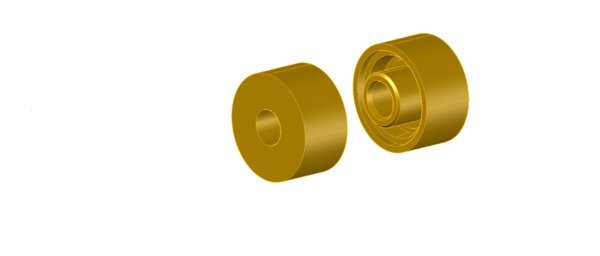

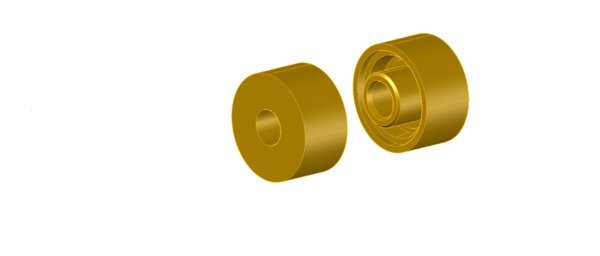

They will wind up being machined like this.

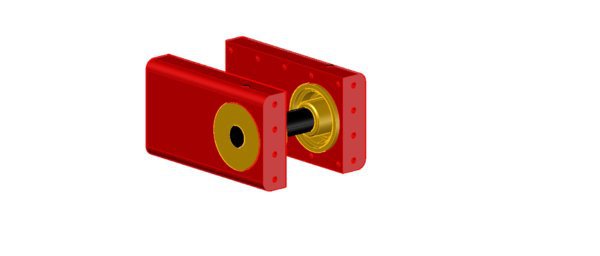

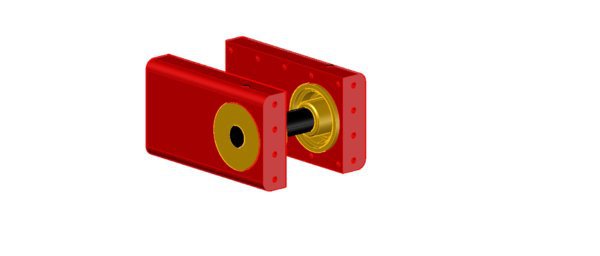

And will then be pressed into the Guides.

1 down and 3 to go.

I have all the material now to do the rebuild and just parted 4 pieces of 3.5" 4340 for the front axle holders.

They will wind up being machined like this.

And will then be pressed into the Guides.

1 down and 3 to go.

Last edited: