- Joined

- Jul 20, 2014

- Messages

- 1,386

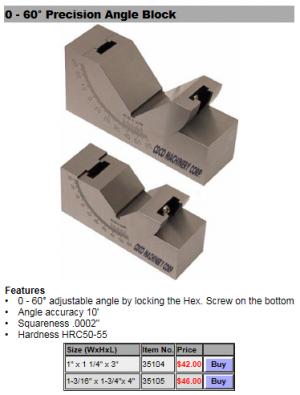

This is an operation on the mill that I have never attempted. I don't own a sine plate or tilting vise,

so what do I need to mill angles to create 15° and other cuts on steel, e.g. to make a Jacobs style wedge

or toe/edge clamps and similar tools. Can this be done safely and effectively on a tilting vise?

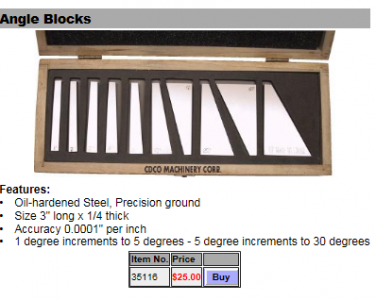

I would rather use a sine plate but the good quality plates are expensive. B&S or Suburban tool.

I may buy a good used plate, small. I see them on Ebay, but then you also need a set of gage blocks.

All this can easily become a $500 purchase. I see no other way to do this type of work accurately.

Thanks.

so what do I need to mill angles to create 15° and other cuts on steel, e.g. to make a Jacobs style wedge

or toe/edge clamps and similar tools. Can this be done safely and effectively on a tilting vise?

I would rather use a sine plate but the good quality plates are expensive. B&S or Suburban tool.

I may buy a good used plate, small. I see them on Ebay, but then you also need a set of gage blocks.

All this can easily become a $500 purchase. I see no other way to do this type of work accurately.

Thanks.