- Joined

- Sep 23, 2010

- Messages

- 619

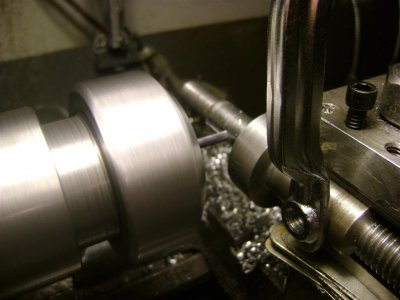

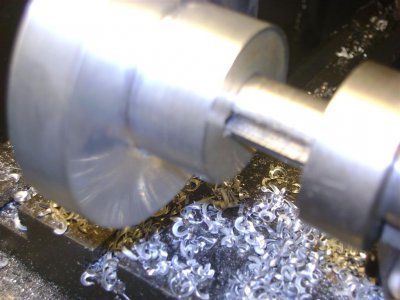

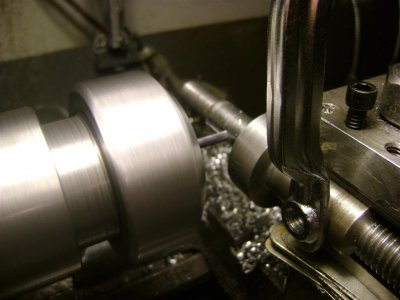

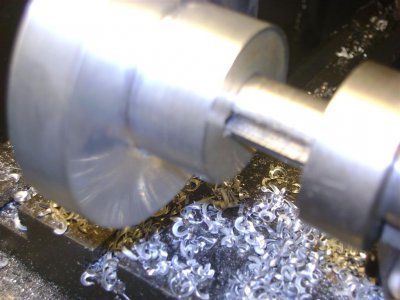

This is my arbor that i make my SB pulleys in and i make 15 or so a year. Well it needed a 3/16" w x 3/32" deep keyway. I could have done it a dozen different ways but thought to use my 10K lathe and take some pics. I started with my home made square tool block and clamped the arbor in it with a cool looking slide clamp i just had to buy. Then i shimmed up the tool block so the center of the shaft was inline with the #3 MT dead center located in my lathes spindle. I used a steel rule to tell if it needed to come up or go down. Then i raised the block until the ruler was plumb (straight up and down for those that don't know). Then i chucked up a 3/16" end mill in my home made ER40 collet chuck (love that thing) and i tightened the gib screws a twang in the cross slide to keep the chatter down. Moved the belt over a few grooves in the pulleys to get the spindle up to speed for the small end mill and proceded to cut the slot. Took about 5 cuts until it was deep enough to measure with my steel ruler. Perfect fit...Bob