- Joined

- Apr 9, 2017

- Messages

- 42

I have a teeny 5/16" deep cut-off blade in a wee little holder on my 7x10... needed something a bit bigger for many jobs, picked up the JUMBO cut-off tool from MicroMark. .. a whole 1/2" deep.

Should I return it?

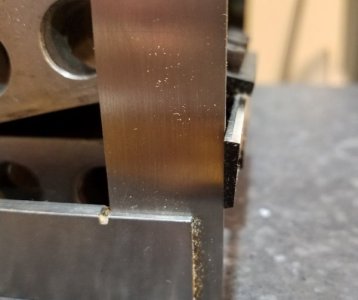

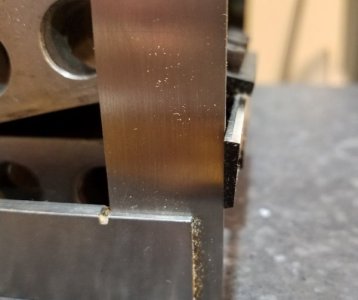

Looks funky to me... the holder clamps up squarely in my 3/8" tool holder, but the blade sits at a weird angle... could work, is it supposed to be like this?

One side is about perfectly vertical (no clearance), the other side leans way over. And it has a peaked (convex not concave) upper surface, which presents as 1/2 flat, 1/2 leaning over.

And the holder seems hard, don't really want to anneal it to machine an angle on the tab...

Should I return it?

Looks funky to me... the holder clamps up squarely in my 3/8" tool holder, but the blade sits at a weird angle... could work, is it supposed to be like this?

One side is about perfectly vertical (no clearance), the other side leans way over. And it has a peaked (convex not concave) upper surface, which presents as 1/2 flat, 1/2 leaning over.

And the holder seems hard, don't really want to anneal it to machine an angle on the tab...