- Joined

- Dec 3, 2023

- Messages

- 81

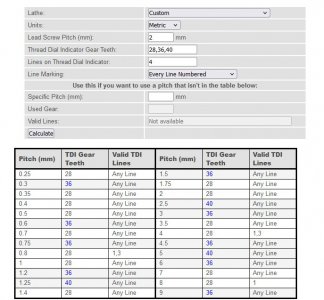

My metric lathe has a 2mm lead screw, and I am currently working on acquiring all the thread dial gears made for my lathe. They are 28, 36, and 40 tooth gears. I've been reading up on metric thread dial information and of course only now I see how much more complex a thread dial is on a metric lathe.

One of the informative explanations I read was that imperial threads are fractional because they are threads per inch, so they lend themselves to the fractional nature of the 360 degree dial marking system. But, metric threads are not fractional based thread sizes so they aren't as intuitive.... I don't completely understand this at a high enough level to understand all the implications.

I can see where having a 3mm lead screw would give you some crazy fractions to translate to a thread dial. I have a 2mm lead screw, and that seems like it could yield some workable fractions on a thread dial...

Is a 2mm lead screw and 28, 36, and 40 tooth thread dial gears always going to give me a thread dial with the 4 major compass points?? (N, S, E, W) My intuition tells me that I will be able to use the same dial with each gear, but I'm just guessing.

Anyone have a firm grip on metric thread dials and particularly the idea of a 2mm lead screw making a metric thread dial easier to understand?? thanks in advance

One of the informative explanations I read was that imperial threads are fractional because they are threads per inch, so they lend themselves to the fractional nature of the 360 degree dial marking system. But, metric threads are not fractional based thread sizes so they aren't as intuitive.... I don't completely understand this at a high enough level to understand all the implications.

I can see where having a 3mm lead screw would give you some crazy fractions to translate to a thread dial. I have a 2mm lead screw, and that seems like it could yield some workable fractions on a thread dial...

Is a 2mm lead screw and 28, 36, and 40 tooth thread dial gears always going to give me a thread dial with the 4 major compass points?? (N, S, E, W) My intuition tells me that I will be able to use the same dial with each gear, but I'm just guessing.

Anyone have a firm grip on metric thread dials and particularly the idea of a 2mm lead screw making a metric thread dial easier to understand?? thanks in advance