A

Andre

Forum Guest

Register Today

[h=1]Andre[/h][h=4]Metal Scraping, Why and How-To[/h][h=6]Rate this Entry[/h]1 Comment

by Andre

, 05-25-14 at 12:52 PM (11 Views)Metal Scraping, Why and How-To.

What is Metal Scraping?

Metal scraping is the process of removing high spots from the work, making it flatter or to conform it to a certain shape (Ie, tapered bearing, V block) in a very precise manner that even a lot of machine tools can not match.

Why?

Scraping does not just create flat surfaces, when properly done, bearing surfaces, oil pockets, and specific wear patterns can be scraped in.

What Tools Do I Need?

The things you will need are a scraper, surface plate or other reference edge like a straightedge, surface plate cleaner, marking medium, a rubber wheeled roller to roll the dye, workholding device, bench stone (or a lapping machine if you use carbide) smaller hand stone to remove burrs after a pass, very good lighting, light solvent for cleaning swarf out of your stones, rags, metrology instruments (indicators, or other tools depending on the job.)

The Scraper.

A good scraper is required for a good scrape job, and it has to work for you.

There are many types of hand and power scrapers to be made or purchased, including Anderson tube scrapers, the Biax power scraper, pull scrapers, etc. In both HSS and carbide.

If you are scraping a lot, or scraping hard materials, carbide is by far your best option. Does not require frequent sharpening, and saves a lot of time. If you are scraping soft steel, aluminum, or gib shim stock (ie, Turcite) HSS is a better option. It can be sharpened to a keener edge, and does not require a lapping machine or diamond stones, but requires frequent sharpenings.

What This Article is About.

This article is for the beginner, to teach the basic principle of hand scraping using common tools to achieve the simple task of flattening the top of a plate. I will not go into moving planes, shifting surfaces, etc. in this article.

Before we begin the article, I have to crush your hopes and dreams. Scraping is not a pretty activity. It's backbreaking, tiring, hard work, laborious, and messy. You will have transfer dye all over the walls, on everything you touch, black hands for awhile from touching a lot of metal and endless frustration. It's not fun, but the final product is more than worth it, trust me!

Lets Begin

First, prepare your scraper. Make sure it's sharp, and that it's comfortable. If it's not sharp, you will be scratching not scraping, never getting anywhere.

Preparing your work

Prepare your work by feeling for and stoning dings, and slightly stoning the edges to keep them from cutting yourself. If there is rust on the work, scrape a few passes without marking for high spots over the entire surface to remove it.

Make sure to sharpen your scraper often, as iron oxide is highly abrasive (grinding wheels are made from it). This process for rust removal also gives you a feel for your scraper.

After scraping to remove rust, stone the surface to remove dings created when the scraper stops, this has to be done after every scraping pass throughout the job. Then clean the surface with paint thinner or other thin solvent.

Surface Plate Preperation

Next, prepare your surface plate. There are different types, the most common are cast iron, and granite. Cast iron plates can be cleaned with household glass cleaner (dry thoroughly to prevent rust!) but since granite has a texture, it needs a deeper clean. I like Comet detergent, lightly abrasive so it cleans the plate's texture well. But since it is abrasive it can wear the plate over time if you are not careful. Never use abrasive cleaners on metal plates! It will wear them quickly.

When you clean your surface plate, clean it lightly and wait for it to normalize. When cleaners evaporate from the plate's surface, it chills it (Thats why fast drying solvents feel cold) and can warp the plate. My advice is to clean it, cover it with a very clean sheet or towel to normalize then wipe it with clean hands to make sure there is no lint on the surface.

Inking the Plate

Now that your part and plate are clean, we need to ink the plate with a transfer medium. This will mark all the high spots on your work, showing what needs to be scraped away.

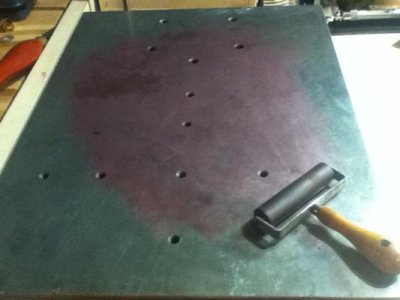

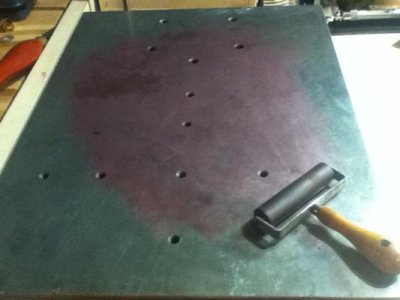

Get an idea of the space on your surface plate you need, and put a few very small touches of dye on the plate inside the area you need. You will soon get a feel for how much marking medium you need. (For my fairly large piece, it took less than a pea sized blob)

Then take your rubber roller and spread the dye. Spread it as thin as possible, but don't go too crazy. Make sure you have an even spread all over the area of the plate you need. You can always take it off if you put too much on.

(Notice the even, thin layer. The dark spot is a stain.)

The Rub

Now one of the most important things about scraping, the rub. This is crucial to a good job, not too hard, not too soft. Not too long, not too short. You'll get a feel for it.

Clean the work well with solvent, dry it then gently put it on the plate. Rub it in a circular or figure-8 pattern to transfer the dye to our work's high spots that will then be scraped away.

Scraping

Now that you have the ink transferred from the plate to the work, you need to scrape. Hold your work down to the bench, put your scraper on the work, and with light to moderate pressure push (or pull) the scraper and watch as a little chip comes off. Since this is a roughing pass, remove all the blue from the work by scraping them off. These are your high spots, and they need to be removed.

After several passes, you will notice the blue start to spread from a few points to cover our entire surface. This is a good sign, it means your getting flatter and flatter. This is when we have to be careful, if we take a pass too deep we can create a lot more work for ourselves.

Spotting

When the blue starts covering the surface in spots, we will start a process called "spotting."

This is not a quick stock removal process, it's only very light scraping to remove the peaks and valleys from the part. The scraping strokes should be smaller and shorter to only remove the blue, with very little removed around the blue to none at all if possible.

Keep doing this untill you have reached your desired level of flatness. This can be done with an indicator, usually a tenths (0.0001) indicator. As a thousandths (0.001) is not precise enough for scraping. I will not go into metrology, as I do not know enough on the subject and do not want to make a fool out of myself.

Once you have reached your desired level of flatness, you are done. You have just completed your first scraping project.

Recap:

1. Work Prep: Remove all rust, dings, nicks, sharp edges, etc.

2. Surface Plate: Prep cleanliness cleanliness cleanliness!

3. Inking the Plate: Spread a thin layer of blue on the plate, in an even and uniform spread.

4. The rub: the most important part in scraping, marking high spots on the work. Make sure everything is very clean! A piece of lint can ruin the work.

5. Scraping: The process of removing high spots, and stock removal in a precise, but coarse manner.

6. Spotting: A more precise version of scraping, removing only the tips of the peaks.

7. Pinpointing: (Not discussed in this article) A form of marking the work by using a material harder than the work to burnish the high spots. This can bring a much flatter surface than high spot blue, but is not needed in most cases.

by Andre

, 05-25-14 at 12:52 PM (11 Views)Metal Scraping, Why and How-To.

What is Metal Scraping?

Metal scraping is the process of removing high spots from the work, making it flatter or to conform it to a certain shape (Ie, tapered bearing, V block) in a very precise manner that even a lot of machine tools can not match.

Why?

Scraping does not just create flat surfaces, when properly done, bearing surfaces, oil pockets, and specific wear patterns can be scraped in.

What Tools Do I Need?

The things you will need are a scraper, surface plate or other reference edge like a straightedge, surface plate cleaner, marking medium, a rubber wheeled roller to roll the dye, workholding device, bench stone (or a lapping machine if you use carbide) smaller hand stone to remove burrs after a pass, very good lighting, light solvent for cleaning swarf out of your stones, rags, metrology instruments (indicators, or other tools depending on the job.)

The Scraper.

A good scraper is required for a good scrape job, and it has to work for you.

There are many types of hand and power scrapers to be made or purchased, including Anderson tube scrapers, the Biax power scraper, pull scrapers, etc. In both HSS and carbide.

If you are scraping a lot, or scraping hard materials, carbide is by far your best option. Does not require frequent sharpening, and saves a lot of time. If you are scraping soft steel, aluminum, or gib shim stock (ie, Turcite) HSS is a better option. It can be sharpened to a keener edge, and does not require a lapping machine or diamond stones, but requires frequent sharpenings.

What This Article is About.

This article is for the beginner, to teach the basic principle of hand scraping using common tools to achieve the simple task of flattening the top of a plate. I will not go into moving planes, shifting surfaces, etc. in this article.

Before we begin the article, I have to crush your hopes and dreams. Scraping is not a pretty activity. It's backbreaking, tiring, hard work, laborious, and messy. You will have transfer dye all over the walls, on everything you touch, black hands for awhile from touching a lot of metal and endless frustration. It's not fun, but the final product is more than worth it, trust me!

Lets Begin

First, prepare your scraper. Make sure it's sharp, and that it's comfortable. If it's not sharp, you will be scratching not scraping, never getting anywhere.

Preparing your work

Prepare your work by feeling for and stoning dings, and slightly stoning the edges to keep them from cutting yourself. If there is rust on the work, scrape a few passes without marking for high spots over the entire surface to remove it.

Make sure to sharpen your scraper often, as iron oxide is highly abrasive (grinding wheels are made from it). This process for rust removal also gives you a feel for your scraper.

After scraping to remove rust, stone the surface to remove dings created when the scraper stops, this has to be done after every scraping pass throughout the job. Then clean the surface with paint thinner or other thin solvent.

Surface Plate Preperation

Next, prepare your surface plate. There are different types, the most common are cast iron, and granite. Cast iron plates can be cleaned with household glass cleaner (dry thoroughly to prevent rust!) but since granite has a texture, it needs a deeper clean. I like Comet detergent, lightly abrasive so it cleans the plate's texture well. But since it is abrasive it can wear the plate over time if you are not careful. Never use abrasive cleaners on metal plates! It will wear them quickly.

When you clean your surface plate, clean it lightly and wait for it to normalize. When cleaners evaporate from the plate's surface, it chills it (Thats why fast drying solvents feel cold) and can warp the plate. My advice is to clean it, cover it with a very clean sheet or towel to normalize then wipe it with clean hands to make sure there is no lint on the surface.

Inking the Plate

Now that your part and plate are clean, we need to ink the plate with a transfer medium. This will mark all the high spots on your work, showing what needs to be scraped away.

Get an idea of the space on your surface plate you need, and put a few very small touches of dye on the plate inside the area you need. You will soon get a feel for how much marking medium you need. (For my fairly large piece, it took less than a pea sized blob)

Then take your rubber roller and spread the dye. Spread it as thin as possible, but don't go too crazy. Make sure you have an even spread all over the area of the plate you need. You can always take it off if you put too much on.

(Notice the even, thin layer. The dark spot is a stain.)

The Rub

Now one of the most important things about scraping, the rub. This is crucial to a good job, not too hard, not too soft. Not too long, not too short. You'll get a feel for it.

Clean the work well with solvent, dry it then gently put it on the plate. Rub it in a circular or figure-8 pattern to transfer the dye to our work's high spots that will then be scraped away.

Scraping

Now that you have the ink transferred from the plate to the work, you need to scrape. Hold your work down to the bench, put your scraper on the work, and with light to moderate pressure push (or pull) the scraper and watch as a little chip comes off. Since this is a roughing pass, remove all the blue from the work by scraping them off. These are your high spots, and they need to be removed.

After several passes, you will notice the blue start to spread from a few points to cover our entire surface. This is a good sign, it means your getting flatter and flatter. This is when we have to be careful, if we take a pass too deep we can create a lot more work for ourselves.

Spotting

When the blue starts covering the surface in spots, we will start a process called "spotting."

This is not a quick stock removal process, it's only very light scraping to remove the peaks and valleys from the part. The scraping strokes should be smaller and shorter to only remove the blue, with very little removed around the blue to none at all if possible.

Keep doing this untill you have reached your desired level of flatness. This can be done with an indicator, usually a tenths (0.0001) indicator. As a thousandths (0.001) is not precise enough for scraping. I will not go into metrology, as I do not know enough on the subject and do not want to make a fool out of myself.

Once you have reached your desired level of flatness, you are done. You have just completed your first scraping project.

Recap:

1. Work Prep: Remove all rust, dings, nicks, sharp edges, etc.

2. Surface Plate: Prep cleanliness cleanliness cleanliness!

3. Inking the Plate: Spread a thin layer of blue on the plate, in an even and uniform spread.

4. The rub: the most important part in scraping, marking high spots on the work. Make sure everything is very clean! A piece of lint can ruin the work.

5. Scraping: The process of removing high spots, and stock removal in a precise, but coarse manner.

6. Spotting: A more precise version of scraping, removing only the tips of the peaks.

7. Pinpointing: (Not discussed in this article) A form of marking the work by using a material harder than the work to burnish the high spots. This can bring a much flatter surface than high spot blue, but is not needed in most cases.

Last edited by a moderator: